Nanomaterialien für grüne Energie

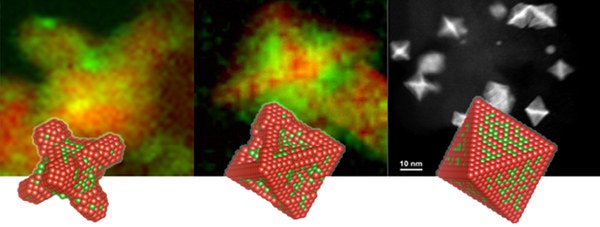

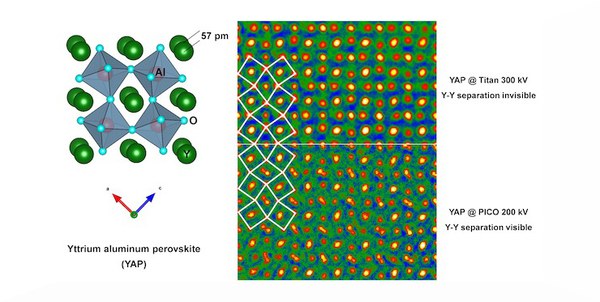

Die Eigenschaften neuer Materialien für die Energieumwandlung und -speicherung sind sehr oft mit ihrer Struktur auf atomarer Ebene verknüpft. Ein Beispiel hierfür sind neuartige Brennstoffzellenkatalysatoren. Hochauflösende analytische In-situ-Elektronenmikroskopie hilft uns dabei, solche Materialien unter realistischen Arbeitsbedingungen zu verstehen.