Modeling of the bainitic transformation during press hardening

The development of advanced press hardening technology is of great interest to the automotive industry as it provides an efficient process for producing medium to high strength steel parts that can meet the increasing demand for lightweight chassis. In press hardening, an austenitized steel sheet is stamped using controlled-temperature tools in which austenite transforms into martensite, bainite or ferrite under mechanical stress in a rapid cooling cycle. The proportions of these micro-components depend on the process parameters and can strongly influence the final properties. Therefore, it is important to understand the bainitic transformation under complex cooling and loading conditions.

We have combined modeling at different scales to provide a roadmap for the chemical-mechanical interaction of the bainitic press hardening process. Quantitative description of microstructural evolution in this process requires the development of novel modeling techniques to properly capture the interaction of phase transformation kinetics and thermodynamics, elastic and plastic deformation, and chemical effects due to alloying. They provide a basis for understanding phase transformation kinetics with full consideration of thermo-chemo-mechanical coupling at all length scales. In particular, we were able to show:

- At the smallest scale, ab initio methods can be used for parameter-free prediction of elastic parameters with an extension towards large deformations. A cross-scale consideration with a comparison to classical density functional theory and phase-field crystal methods provides a thorough understanding and quantitative analytical description of stress-strain relationships that can serve as a basis for modeling microstructure evolution at higher scales.

- In-depth analysis of EBSD-measured microstructure data with respect to the crystallography of bainitic transformation enables a mathematical description of transformation plasticity as a result of orientation variant selection by applied stresses. Furthermore, we extract the variant selection mechanisms that are central to the formulation of the mesoscopic descriptions.

- Proximity to interfaces, e.g. ferrite-austenite interfaces or grain boundaries, can affect the local thermodynamics of carbide precipitation via an elastic interaction. We show how these scale bridging effects can be effectively formulated for exploiting the equilibrium properties and precipitation kinetics of carbides near surfaces and interfaces under the influence of external and internal stresses.

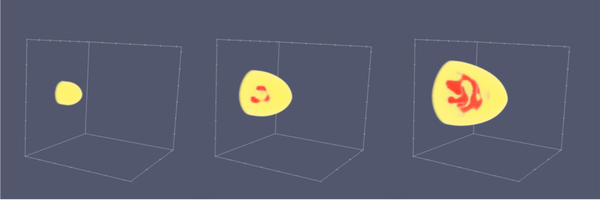

- Thermodynamically consistent phase field descriptions using non-diagonal interactions allow the descriptions to be quantitatively and consistently related to sharp interfacial models even in the region of finite diffusion contrasts in the phases. Based on the phase field models, we have investigated the role of mechanical stresses on the phase transformation kinetics at the level of carbide precipitates with controlled consideration of elastic and plastic interactions.

Reference: Lin,M.;Zimmermann,C.; Wang, K.; Hunkel, M.; Prahl, U.; Spatschek, R. Modeling Bainitic Transformations during Press Hardening. Materials 2021, 14, 654. https://doi.org/10.3390/ma14030654