Fabrication of 3D oriented pore structure by using freeze casting method and characterization of tunable mechanical properties

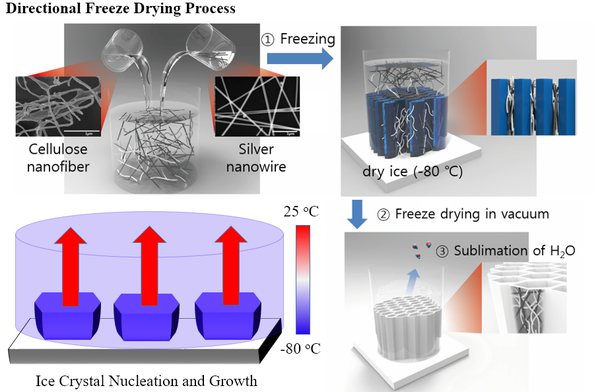

By employing a directional freeze-casting technique, nanomaterials uniformly dispersed in water can be transformed into three-dimensional, porous, lightweight architectures, wherein the regions occupied by ice crystals become pores following sublimation under controlled conditions. The resulting architectures can exhibit a wide range of mechanical properties, governed by parameters such as pore orientation and size, wall thickness within the hierarchical structure, and the compositional ratio of the incorporated nanomaterials.

In one representative study employing this concept, a three-dimensional porous architecture was fabricated by integrating silver nanowires—one-dimensional nanomaterials with diameters on the order of several tens of nanometers and lengths in the micron range—with cellulose nanofibers. The resulting structure exhibited a pronounced reinforcement effect, with mechanical strength modulated by pore orientation and enhanced with increasing silver nanowire content. Notably, its strength-to-relative density ratio was comparable to that of metallic microlattices possessing hollow hierarchical architectures, which have been previously proposed as ultralight, high-strength structures composed of over 99% air.

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 108

Source: Kim T. et al., Extreme Mechanics Letters 2019, 30, 100512