Forget trial and error – On the benefits of Machine Learning for Phase Field nucleation simulation

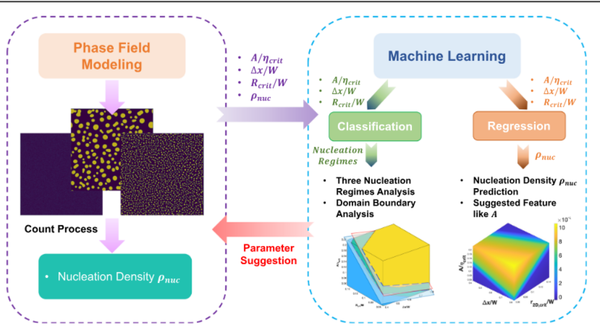

We conducted a study to introduce a data‑driven approach that employs machine learning (ML) to streamline and enhance phase field simulations of oxide nucleation in Fe–Cr alloys. Therefore, we used a grand potential–based phase field model enriched with Langevin thermal noise to simulate oxide nuclei formation, validating results against the classical Johnson–Mehl–Avrami–Kolmogorov (JMAK) theory.

Three key parameters (Langevin noise strength, numerical grid spacing, and critical nucleation radius) were identified as crucial determinants of nucleation behavior. These were used as input features for both classification and regression ML models. The classification model effectively segmented nucleation outcomes into “no nucleation,” “medium density,” and “high density” regimes, helping avoid inefficient or invalid simulation attempts. Meanwhile, the regression model could accurately predict the needed noise strength, dramatically reducing time-consuming trial-and-error simulations.

By integrating ML into phase field modeling, our study significantly accelerates parameter selection, minimizing extensive computation. This enhances the efficiency and reliability of simulating microstructural evolution and offers a generalizable method applicable across various materials and nucleation-driven processes.

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 101

DOI 10.1038/s41529-024-00529-8