Frontiers of material characterization: How to measure ceramic tape properties reliably

The nature of solid-state batteries components makes material characterization very difficult. Solid electrolytes used as separator material are usually less than 100 µm thick and, in the case of NZSP, LATP, and LLZO, sensitive to air exposure. Furthermore in the cathode composite the solid electrolyte has a porosity above 50%, while ceramic active material like LFP or NVP is loosely sintered with grainsizes in the 100 nm range. Due to these material properties, conventional ASTM-compliant characterization methods cannot be used. Instead, the limits of the measurement methodology must be expanded.

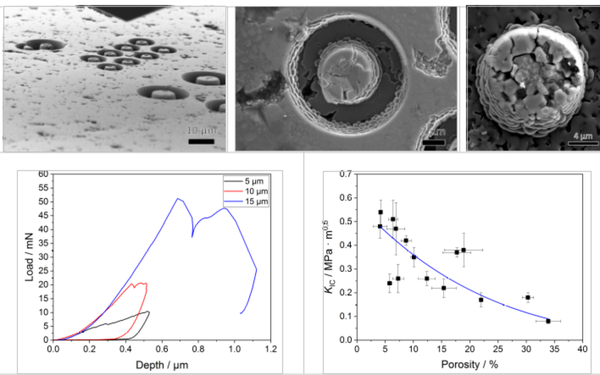

Using newly developed micro bending rigs the fracture strength of ceramic samples down to a minimal thickness of 50 µm can be characterized. Statistical analysis of the strength values allows conclusions to be drawn about edge effects, such as the influence of laser cutting on the sample properties as well as the near-surface defect size distribution in the sample, or the reliability of the material in operation.

The micropillar splitting technique is used for local measurements of the materials fracture toughness. Pillars with smaller diameters can be used to analyze the fracture toughness of certain microstructural features, such as grain boundaries, whereas larger pillar diameters can be used to determine values that are representative of the entire sample. The reliability of this method when applied to porous samples is currently being investigated, as is the question of how far the pillar diameter can be reduced before the results become invalid.

Dr. Jürgen Malzbender

Group Leader Ceramic Materials

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 165

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 169