HiperFer steel for concentrating solar power applications

The overall efficiency of commercial concentrating solar power (CSP) plants is currently limited by the performance of structural materials operating at process temperatures above 600 °C. To increase the competitiveness of CSP technology, it is crucial to lower material costs while enhancing the durability of metallic components exposed to molten solar salt. A promising pathway is the use of cost-effective, Al-alloyed high-performance ferritic salt-corrosion-resistant steels (HiperFerSCR) as an alternative to more expensive austenitic grades.

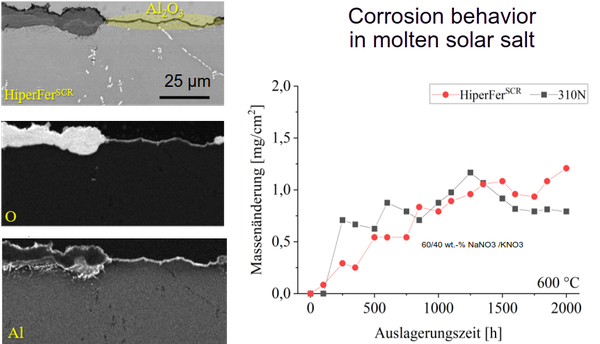

Salt-corrosion tests in molten solar salt (60/40 wt.% NaNO₃/KNO₃) at 600 °C for up to 2,000 hours demonstrated that HiperFerSCR shows corrosion behavior comparable to the costly austenitic commercial steel 310N. This performance is attributed to the formation of a stable protective Al₂O₃ layer, which is significantly less soluble in molten salt than the Cr₂O₃ scale typically formed on austenitic steels.

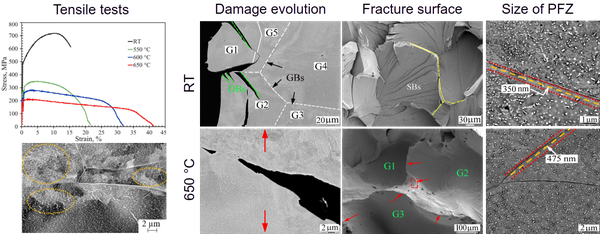

Mechanical testing revealed that HiperFerSCR exhibits strain softening and grain-boundary decohesion at 550–650 °C, whereas at room temperature it undergoes strain hardening. The latter is driven by the presence of finely dispersed Laves-phase particles, which promote planar slip and facilitate damage initiation at slip bands. Laves phase particles are determining the deformation and damage modes in HiperFerSCR steel and emphasising the significance of reducing the particle free zone (PFZ) to limit grain boundary decohesion at high temperatures.

Dr.-Ing. Tarek Allam

Group Leader "Sustainable Alloys for Energy Technologies"

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 112

Source: https://doi.org/10.1016/j.msea.2024.146771