Linking the material processing to the microstructural and mechanical properties

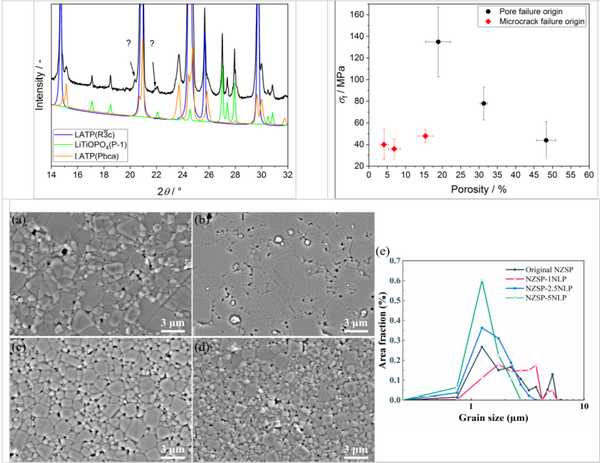

One promising processing technique for the large scale production of thin ceramic battery components is the tape cast process. With this processing route, the properties of the ceramic depend largely on the production and processing of the starting powder, the composition of the tape cast slurry, the casting speed, and the sintering parameters. Moreover, sintering additives are utilized to achieve a reduction in the required temperature while simultaneously increase densification during sintering. This is especially relevant for material with a strong anisotropy in the thermal expansion coefficient as high temperatures can lead to severe cracking of the sample upon cooling down. This was in detail analyzed for the NaSICON-type solid electrolyte LATP. Herby varying amounts of LiF, SiO2, Li2WO4 as well as Li2B2O4 were used as sintering additives. The use of these additives resulted in the formation of a previously unknown orthorhombic LATP modification which exhibited a significantly lower ionic conductivity. The formation of the orthorhombic phase could be linked to increased lithium content and reduced sintering temperatures. Due to the liquid sintering conditions induced by the usage of the sintering additives, a higher densification could be achieved, which was however manly driven by an enhanced Oswald ripening resulting in abnormal grain growth and sever cracking in the samples. The microcracks in the material lead to a decrease of the materials’ strength from ~140 MPa to ~ 40 MPa.

Using non Li- or Na-containing additives seems to be more promising. In the isostructural NaSICON material NZSP the usage of Na3LaP2O8 as a sinter additive leads to increased densification and higher ionic conductivity, without increased grain growth,thereby preventing crack formation. Using these types of “non-active” sinter additives is a promising new approach, which is currently under further investigation. Above all the precise mechanism how these additives alter the sintering need to be understood.

Dr. Jürgen Malzbender

Group Leader Ceramic Materials

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 165

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 169