Machine Learning: Microstructure and mechanical properties of pearlite

This study aims to develop a novel approach using machine learning-based methods to enhance the visualization and understanding of the microstructure and mechanical properties of pearlite structure. While pearlitic steels have been extensively studied, the quantitative analysis of how cementite lamellae morphology influences mechanical properties remains incomplete. This approach represents the first known application of a neural network for the segmentation of cementite lamellae within pearlite, enabling high-precision, automated extraction of microstructural features that are traditionally difficult to quantify using conventional image analysis techniques.

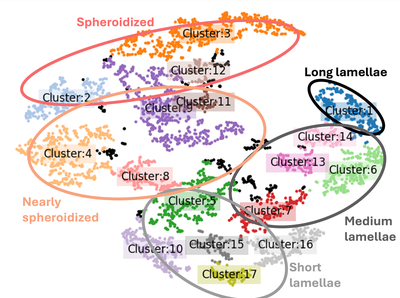

The clustering analysis of the pearlitic microstructure, derived from its two-dimensional features using advanced computational algorithms, resulted in the identification of 17 distinct clusters. These clusters were visualized as colorful dots, and any data points identified as outliers were distinctly labeled in black.

High-resolution microstructural data were acquired using scanning electron microscopy (SEM) and electron backscatter diffraction (EBSD), while mechanical properties were characterized via nanoindentation to obtain localized hardness measurements. The workflow begins with advanced image segmentation to isolate cementite lamellae from high-resolution microscopy images, enabling detailed morphological quantification. Random Forest classifier and U-Net architecture were applied for this segmentation task. The performance was evaluated and compared, and a hybrid approach combining both methods was proposed and yielded improved segmentation accuracy.

Morphological features of cementite extracted from the segmented images were subsequently clustered using unsupervised learning to identify characteristic microstructural patterns. Not only it allows a better colony identification and morphology visualization, but also morphological features are then quantitatively linked to localized hardness analysis. It has been found that the variation of hardness among pearlite colonies cannot be accounted for solely by the different interlamellar spacing size, and is related to lamellar continuity, spheroidization degree and ferrite crystal orientation.

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 113