Microstructure engineering of Ni-lean stainless steel for enhanced hydrogen embrittlement resistance

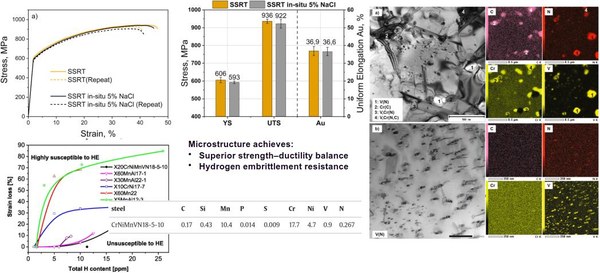

Hydrogen-induced property degradation poses a major challenge in development of high-strength and reliable metallic materials for hydrogen-related applications. A novel Ni-lean, medium-Mn austenitic stainless steel was developed and processed to combine the excellent mechanical properties of high-Mn steels with the high corrosion resistance of conventional stainless steels, while also exhibiting superior resistance to hydrogen-embrittlement (HE) compared to both steel classes. The developed steel (X20CrNiMnVN18-5-10) shows the lowest susceptibility to HE, evaluated by the strain loss as a function of increasing total hydrogen content, when compared to conventional stainless steel (X10CrNi17-7) and various grades of medium- and high-Mn steels. This enhanced HE resistance was achieved by engineering the microstructure through a controlled alloy and process design, promoting the formation of multiple types of irreversible hydrogen traps (V- and Cr-based precipitates, 20 – 300 nm in size) within an ultrafine-grained matrix.

Dr.-Ing. Tarek Allam

Group Leader "Sustainable Alloys for Energy Technologies"

- Institute of Energy Materials and Devices (IMD)

- Structure and Function of Materials (IMD-1)

Room 112

Source: https://doi.org/10.1016/j.jmrt.2020.09.085 & https://doi.org/10.1016/j.msea.2023.145203