Manufacturing Technologies

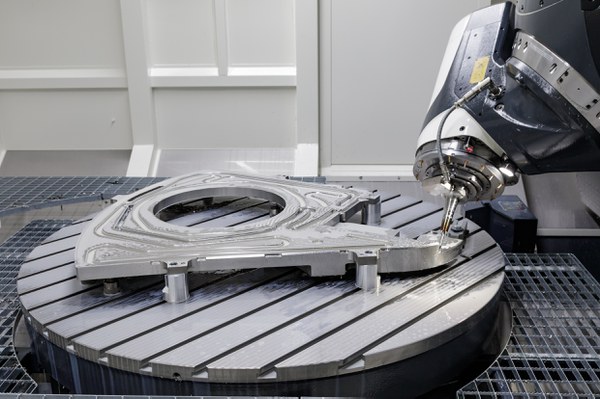

The majority of our projects are multi-year projects to develop large-scale research facilities. In addition to components, experiments, instruments, equipment and processes are also developed and manufactured across technological boundaries.

In addition to our employees' broad methodological expertise, machinery and technological equipment, our unique selling point is that we work according to a holistic understanding of products and processes. This is based on numerous processes, for example, in order to achieve a production-oriented design. This means that information constantly circulates along the product development process through all disciplines and across team boundaries.

Particularly in prototype development on the edge of what is physically feasible, permanent coordination of feasibility and, if necessary, early testing with production and, if necessary, (further) development of production technologies is essential.

Whether it is the processing of exotic and difficult-to-machine materials or the micromachining of components < 0.1 mm: Our daily business and part of our constantly new challenges is to constantly push the boundaries of what is physically possible a little further using new machining concepts and strategies.

Cutting with Light

Precision laser processing in the ZEA-1.

The processing of foils and sheets with a material thickness of a few hundredths but also up to 3 mm, high-precision and complex geometries, thinnest slits and webs, ... These are all requirements that can be met in the ZEA-1 with the help of the laser fine cutting system. The 150W fiber laser generates a laser beam with a diameter of just a few 1/1000mm. Thanks to its construction with granite components and state-of-the-art linear and measuring technology, the system achieves maximum precision.

Cutting with electricity

Electrical discharge machining using wire and die-sinking EDM in the ZEA-1.

These tools are thinner than a hair.

Materials that are very difficult or impossible to machine find their place in the electrical discharge machining of the ZEA-1. High precision and the ability to achieve extremely high surface quality are characteristics of wire and die-sinking EDM. All electrically conductive materials can be machined here. Properties such as the hardness of the material are irrelevant.

Projects

Contact