Additive Quadruples Lithium-Ion Battery Life

Electrolyte additive 3-Thiophen boric acid quadruples life and reduces capacity loss of lithium-ion battery

09 August 2023 – In a collaborative project, researchers from Helmholtz Institute Münster (HI MS; IEK-12) of Forschungszentrum Jülich and MEET Battery Research Center of the University of Münster were able to characterise an additive-based interphase on nickel-rich cathodes in lithium-ion batteries (LIB) using operando SHINERS measurements and gain important insights into the formation mechanisms of the interphase. In addition, it was shown that the lifetime of LIB can be quadrupled and the capacity loss reduced by adding the film-forming electrolyte additive 3-thiophen-boric acid.

Use of Electrolyte Additives and Advanced Measurement Methods

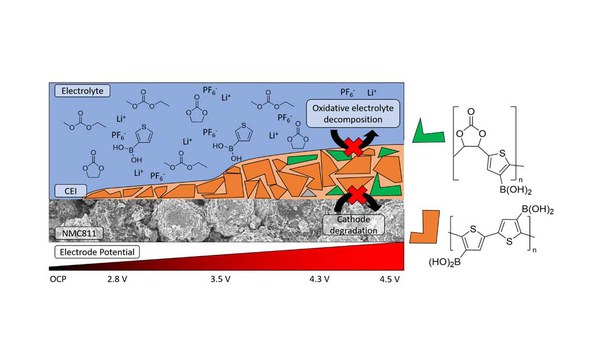

The cathode-electrolyte interphase (CEI) is increasingly becoming a focus of battery research. Electrolytes and cathode materials commonly used in LIB show increased decomposition at high cell voltages, which reduces their lifetime and performance. By using suitable electrolyte additives, a stable and effective interphase is formed on the cathode surface and undesirable processes are suppressed.

The formation of additive-based interphases under real working conditions in LIB could be investigated and characterised for the study using operando SHINERS measurements. This advanced Raman variant provides a wealth of information about the interphase and its formation mechanisms. Only by (further) developing measurement methods that allow the investigation of LIB under real working conditions new insights into the underlying mechanisms in LIB can be gained.

Potential of Passivating Interphases

Scientists from different research areas investigated an interphase based on the additive 3-thiophene-boric acid on the surface of nickel-rich cathodes in order to identify the different components of the interphase and to better understand its formation and action mechanisms. In addition, the influence of the additive used on the performance and lifetime of high-voltage LIB was illuminated.

It was shown that the addition of an optimised concentration of the additive quadruples the lifetime of the LIBs investigated and greatly reduces the capacity loss, compared to the reference system. In addition, the additive showed improved performance in the study compared to standard additives.

Additive-Based Polymer Protects Electrolyte and Cathode from Decomposition Processes

"The SHINERS measurements show that the additive polymerises on the cathode surface and forms an effective interphase. It protects both the electrolyte and the cathode surface from processes that can lead to an early and rapid loss of capacity of the LIB," explains Felix Pfeiffer from the Young Investigator Group "Interfacial Spectroelectrochemistry" at Helmholtz Institute Münster.

In addition, the formation of a copolymer could be demonstrated. It consists of additive and electrolyte solvent molecules. Compared to the purely additive-based polymer, however, only a small proportion of this polymer is formed and only at high cell voltages.

Cooperation between Helmholtz Institute Münster and MEET Battery Research Center

The study was accompanied by quantum mechanical calculations by Dr Diddo Diddens, Helmholtz Institute Münster. The "Interfaces and Interphases" group led by Dr Isidora Cekic-Laskovic, also from Helmholtz Institute Münster, supported the data analysis. Lars Frankenstein from the MEET Battery Research Center of the University of Münster investigated cathodes using SEM and EDX measurements.

Study Published in Advanced Energy Materials

The researchers Felix Pfeiffer, Dr Diddo Diddens, Matthias Weiling, Sebastian Kühn, Dr Isidora Cekic-Laskovic, Masoud Baghernejad, Helmholtz Institute Münster (HI MS; IEK-12) of Forschungszentrum Jülich, and Lars Frankenstein, MEET Battery Research Center of the University of Münster, have published the detailed results of their study as an open access article in the journal Advanced Energy Materials.