BMBF Project on Process Optimisation in Battery Cell Production Launched

The BMBF project "Integrated and accelerated process optimisation for the production of prelithiated electrodes for energy storage systems using machine learning methods", or "InProMal" for short, was launched in February 2023.

25 April 2023 – Since February 2023, researchers at Helmholtz Institute Münster (HI MS; IEK-12) of Forschungszentrum Jülich have been working on "integrated and accelerated process optimisation for the production of prelithiated electrodes for energy storage systems using machine learning methods" – the project is called "InProMal" for short. The project is funded with 430,000 euros (funding number 13XP0532B) by the Federal Ministry of Education and Research (BMBF). It is planned to run until January 2026.

Process Optimisation in Battery Production

The HI MS team around Prof. Dr Egbert Figgemeier investigates the central question of how processes within battery production can be effectively optimised. This includes, for example, integrating the new production step of prelithiation into existing cell production processes. The researchers clarify the relationships between material properties, process parameters and cell performance.

Prelithiation of Anodes

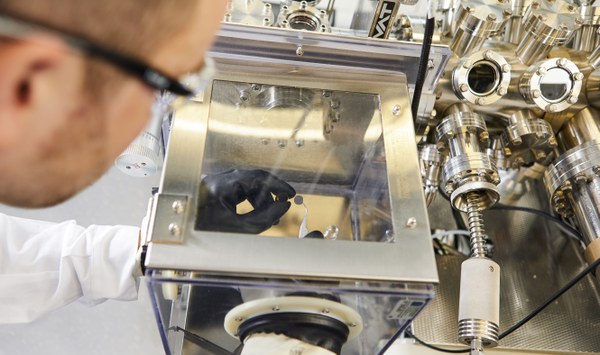

In prelithiation, lithium is added to silicon-containing anodes before battery cell construction and during production. This enables fast-charging capability, higher energy densities and longer lifetimes compared to conventional lithium-ion batteries. However, due to the novelty of the process, the interaction between material development and battery cell production has not yet been optimised.

In InProMal, particularly relevant parameters on the material and process side are to be identified and coordinated with each other with the help of machine learning. It enables the evaluation of large amounts of data and complex structures. "This would not be possible through human labour," explains Figgemeier. "Especially with the novelty of the processes, machine learning is the ideal tool for identifying and understanding interrelationships." The optimised process is precisely coordinated with the material formulation in the project to achieve further progress towards industrial application.

The project is coordinated by BatterieIngenieure GmbH. Other participants besides the Helmholtz Institute Münster are Customcells Itzehoe GmbH and Wacker Chemie AG.