Correlation Between Surface Structure and "Dead" Lithium Demonstrated

Quantitative correlation between surface structure of copper electrodes and deposition of active material lithium in zero-excess lithium metal batteries

24. May 2023 – Researchers from the Helmholtz Institute Münster (HI MS; IEK-12) of Forschungszentrum Jülich and MEET Battery Research Center of the University of Münster show a quantitative correlation between the surface structure of copper electrodes and the deposition of the active material lithium for the first time.

Zero-Excess Batteries Intensively Researched

Since so-called zero-excess lithium metal batteries have a particularly high theoretical specific capacity of 3861 mA h g−1 they receive a lot of attention in research. "Now it has been shown that three-dimensional current collectors with a large surface area help to reduce the deposition of 'dead' lithium, which becomes useless for the battery's function, thus improving its lifetime and minimising safety risks," explains Dr Kerstin Neuhaus from Helmholtz Institute Münster.

'Zero excess' means that a positive electrode fully charged with lithium ions is used, but there is no active material on the negative electrode when the battery is assembled. This consists of copper, for example. Only when the battery is charged for the first time lithium metal is deposited on the copper, which is then oxidised again during discharging and migrates to the cathode.

Decisive Surface Structure

The morphology of the deposits and the formation of the lithium particles, which detach from the negative electrode after a few charging and discharging cycles and are no longer available due to the lack of electrical contact, is decisively determined by the surface structure and chemistry of the copper.

"The larger surface area of the copper electrodes used minimises the formation of dead lithium, as the local current density is reduced by the large surface area and the lithium (re-)deposition becomes more homogeneous, which in turn suppresses the formation of dead lithium," explains Dr Simon Wiemers-Meyer from MEET Battery Research Center.

Cooperation Project

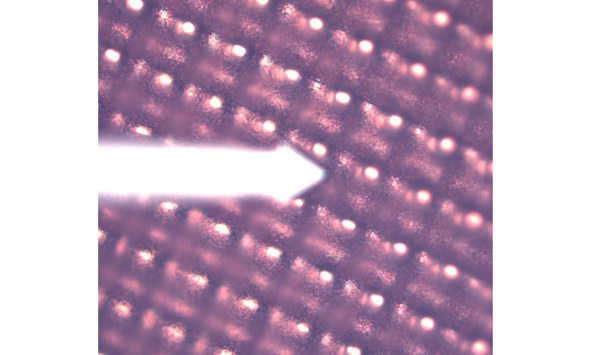

Simon Wiemers-Meyer and Tobias Brake, also from the MEET Battery Research Center, have produced cells with copper foils for the study of the negative electrode. Laser ablation was used to compare microstructured copper foils with untreated foils and the resulting dead lithium was quantified by gas chromatography. The team around Dr Kerstin Neuhaus from Helmholtz Institute Münster in turn contributed to the study by characterising the surface topography of the copper foils using AFM and determining the roughness parameters.

Study Available in Journal of Materials Chemistry A

The detailed results of their study have been published as an open access article in the Journal of Materials Chemistry A by the researchers Christina Schmidt and Dr Kerstin Neuhaus, Helmholtz Institute Münster, Egy Adhitama, Jan Pleie, International Research School BACCARA, Tobias Brake, Feleke Demelash, Dr Simon Wiemers-Meyer, Dr Tobias Placke, MEET Battery Research Center, Prof. Dr Martin Winter, Helmholtz Institute Münster and MEET Battery Research Center, together with authors from other institutes.