Influence of Electrolyte Additive Fluoroethylene Carbonate Varies Depending on Concentration

Analysis of Aging Products Using High-performance Liquid Chromatography

21 November 2025 – Electrolyte additives are the materials of choice for improving the electrochemical stability of batteries and modifying the solid electrolyte interphase (SEI). This layer, which forms between the liquid electrolyte and the solid electrode during the first charging and discharging of the battery, is crucial for its performance, service life, and safety. A team from MEET Battery Research Center at the University of Münster and Helmholtz Institute Münster of Forschungszentrum Jülich has now investigated the influence of the electrolyte additive fluoroethylene carbonate (FEC) in various concentrations – both in high- and lower-voltage applications.

Post Mortem Analysis of Electrolyte Conducted

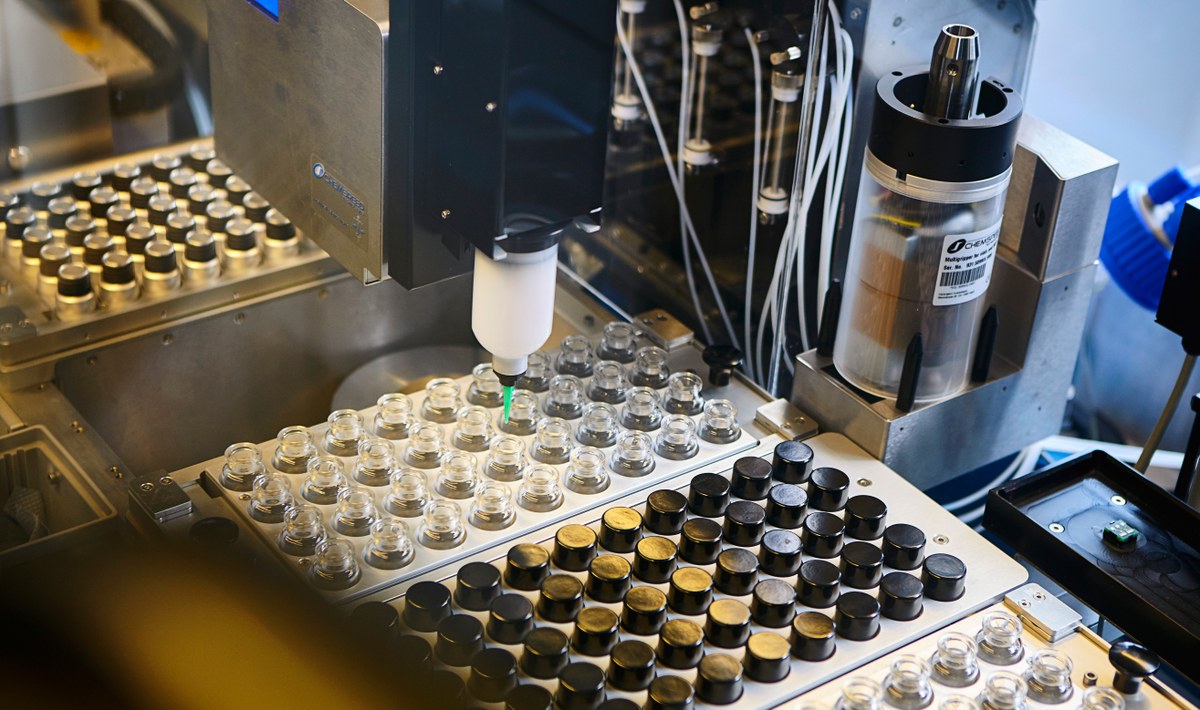

The scientists discovered that electrolytes consisting of similar amounts of ethylene carbonate (EC) and FEC perform poorer in high-voltage applications than the standard electrolyte based on EC and ethyl methyl carbonate. Only when EC is completely replaced by FEC, the performance improves substantially in all applications and thus independently of the voltage. “To classify the results, we extracted the electrolyte and examined it using high-performance liquid chromatography. During this post mortem analysis, we identified aging products that can be related to the reaction between FEC and EC. They explain the poorer electrochemical performance,” explains MEET PhD student Nick Fehlings.

The research conducted by the team follows previous studies in which the standard electrolyte was examined chromatographically. Incorporating the additive FEC into these analyses extends the approach. “This was essential to demonstrate that while FEC works well in low concentrations, high FEC quantities in combination with similar amounts of EC do not perform properly,” says Fehlings. The results represent an important step towards the production of electrolytes that are precisely designed for their specific application.

Entire Study Available

The detailed results have been published by the authors Nick Fehlings, Jakob Hesper, Dr Maximilian Kubot, Dr Simon Wiemers-Meyer und Dr Sascha Nowak, MEET Battery Research Center, Matthias Weiling, Helmholtz Institute Münster, as well as Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, in the journal “Batteries & Supercaps”.