In-situ Electron Microscopy

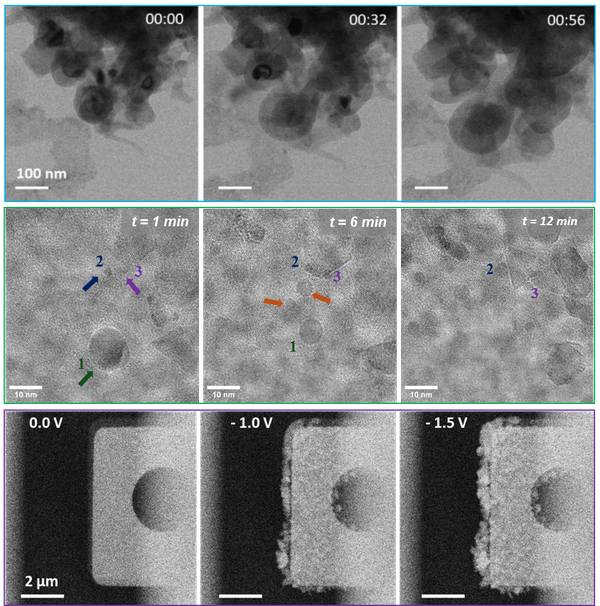

Our research group unlocks the secrets of energy storage and conversion by directly visualizing electrochemical processes in action. By using in-situ laser scanning microscopy (LSM), transmission electron microscopy (TEM), and scanning electron microscopy (SEM), we capture dynamic changes at solid-solid, solid-gas and solid-liquid interfaces within miniaturized electrochemical cells. To bridge the gap between these nanoscale observations and the macroscopic performance of batteries, fuel cells, and electrolyzers, we employ cryo-TEM and focused ion beam (FIB)-SEM tomography to analyze the cell components. This multimodal approach allows us to unravel the mechanisms governing charge transfer and material degradation, and this holistic view is crucial for improving the efficiency and lifespan of these technologies.

We are a dynamic research group dedicated to unraveling the mysteries of energy storage and conversion at the nanoscale. By harnessing the power of advanced microscopy techniques, we aim to revolutionize the development of sustainable energy technologies.

All-Solid-State Battery Research 1,2,3,4

We investigate the critical interfaces within all-solid-state batteries (ASSBs) to understand how to optimize charge transfer and improve their stability. Our in-situ techniques, including gas-phase heating and (dis)charging at a wide range of temperatures, allow us to witness the formation of these interfaces and observe material and interfacial behavior across different temperature ranges. This provides valuable insights into the (electro)chemical stability and performance of various ASSB components. We have also developed a simple screening method based on in-situ TEM to identify the best coating materials for enhanced performance.

Aqueous Battery Research 1,2,3,4

In our research of beyond-lithium batteries, we study (dis)charging processes in aqueous batteries. Our liquid-phase TEM studies provide us with unique opportunities to understand the effects of various factors on battery performance, including optimal charge-discharge routines, current density and mass transport limitations on deposition, role of electrolyte additives in suppressing hydrogen evolution. By observing these fundamental processes at the nanoscale, we aim to develop new strategies to overcome the challenges facing aqueous batteries and improve their overall performance.

Solid Oxide Cell Research 1

Interface instability, catalyst migration, and catalyst poisoning are the main challenges in solid oxide cells working either in solid oxide fuel cell (SOFC) or solid oxide electrolysis cell (SOEC) mode. In our group, we are performing gas phase in-situ TEM experiments at 1 bar pressure to simulate realistic operation conditions and assess futuristic electrode materials. The insights obtained through these in-situ studies, coupled with FIB-SEM tomography, provide a holistic view of different underlying mechanisms, leading to further improvements of those materials.

PEM and AEM Electrolysis Research 1

Low-temperature water electrolysis via proton exchange membrane (PEM) and anion exchange membrane (AEM) has the potential to become the key technology in the sustainable production of "green" hydrogen. One of the current main research focuses of our group is to understand different degradation mechanisms of the Membrane Electrode Assembly (MEA). We are employing (cryo) FIB-SEM tomography, cryo-TEM, in-situ TEM, and in-situ fluorescence microscopy studies to understand the complex interplay of thermal, chemical, and mechanical degradation mechanisms. These understandings, coupled with theoretical studies, aim towards the improvement of MEA technology.

MEMS Fabrication and Hardware Development

The heart of our in-situ capability lies in devices that are based on micro-electromechanic systems (MEMS). We are actively involved in the development of new hardware and MEMS devices, pushing the boundaries of in-situ microscopy. This work is carried out in close collaboration with both academic and industrial partners, fostering innovation and accelerating the translation of research findings into practical applications.

Live Processing and Automation

Our motto as an in-situ group is to develop live processing of the generated images, diffraction, and spectroscopic datasets so that the input stimuli parameters can be adjusted during the experiment itself. This allows us to, for example, compare theoretical growth predictions with experimental results in real-time and dynamically adjust the gas environment during a reaction. We are also working towards automating instruments, allowing for longer duration experiments, increased throughput, and improved reproducibility.

Specialized equipment

- Laser Scanning Microscopy (LSM)

- ZEISS LSM 980

- Leica Stellaris

- Transmission Electron Microscopy (TEM)

- JEOL Grand Arm 2

- JEOL F20

- Scanning Electron Microscopy (SEM)

- TESCAN Mira

- Focused Ion Beam (FIB)

- TESCAN Amber X Cryo Plasma

- ZEISS Cryo Crossbeam

- in-situ SEM and TEM holders

- DENSSolutions B.V. (Climate Infinity, Stream Infinity, Artic, etc.)

- Insight Chips