Against the backdrop of rising greenhouse gas emissions and increasing global energy demand, we are faced with the challenge of accelerating the implementation of the energy transition. To this end, climate-friendly technologies from basic research must be scaled up more quickly and implemented in industrial environments. The holistic technology development and transfer approach LAB2FAB, which sustainably accelerates the innovation cycle from time-consuming, application-free basic research in the LABoratory to practical, industrial use (FACtory), bridges the so-called Technology Readiness Levels (TRL) to the next generation of electrochemical energy storage and converters.

Innovation Space - iNEW

The Innovation Space is dedicated to basic research. Here, new disruptive concepts for novel electrochemical technologies and improved materials for electrodes, electrolytes and catalysts, as well as innovative components are researched in order to further develop and improve existing technologies such as batteries, electrolyzers or fuel cells. An essential part of innovative basic research is the knowledge-driven approach to decipher material-property relationships and the underlying electrochemical processes from ion transport to aging and degradation. Cutting-edge analytics, in-situ / operando technologies (analytics during ongoing operations) and theoretical modeling play a crucial role.

Maker Space - ELECTRA

The Maker Space is the first step on the way to the valorization and industrial implementation of new scientific developments. In the form of a collaborative co-creation space, syntheses, post-processing, workflows, components, and process control are optimized, and efficient electrolysis and fuel cell stacks are developed. A key focus is on high-throughput experiments, rapid prototyping procedures, and industrially scalable process techniques. Furthermore, adapted online analysis techniques for quality control are being developed. A particular focus is on taking future supply chains into account, with closed material cycles, taking material recycling into account, playing an important role.

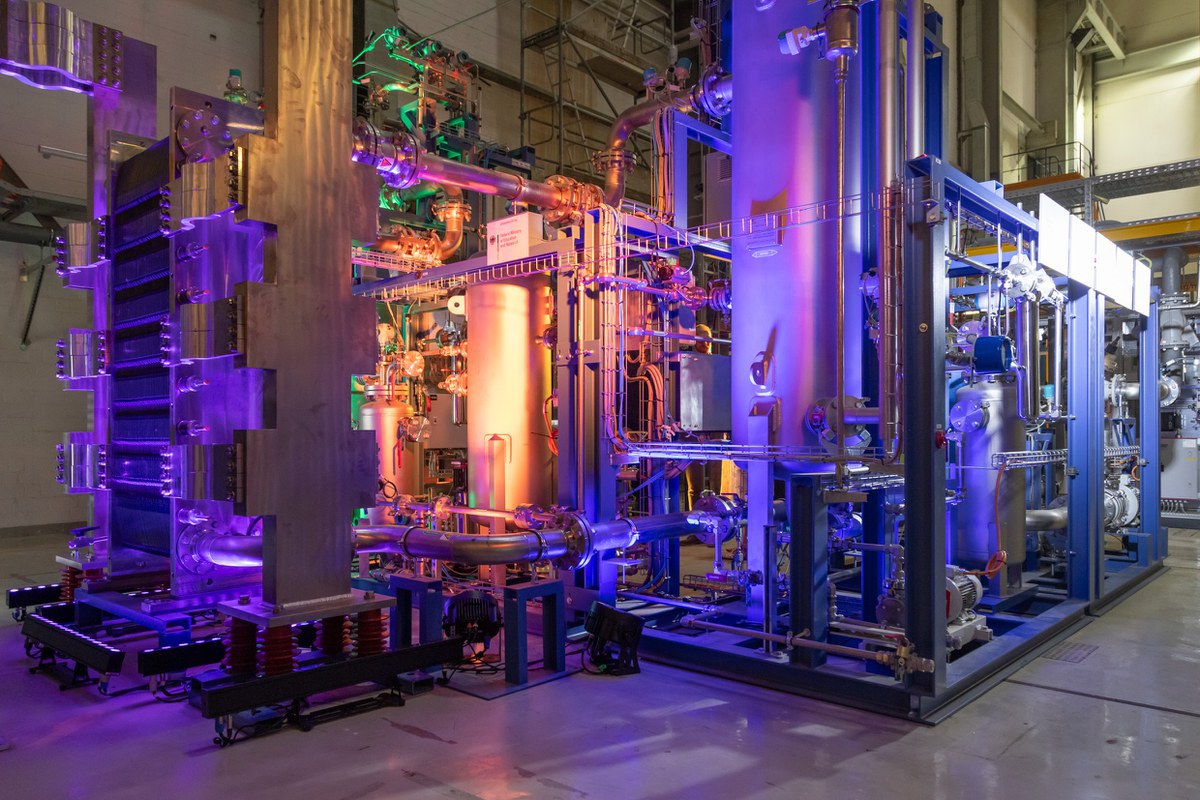

Launch Space - PHOENIX

The Launch Space provides the starting point for rolling out novel electrochemical technologies. For this purpose, demonstrators are developed, set up, and operated in order to carry out comprehensive de-risking. As part of long-term testing, performance, aging, degradation, and the transfer from controlled, ideal laboratory conditions to realistic industrial operating conditions are examined in a real laboratory approach. To ensure that the electrochemical systems can withstand the real requirements and loads, another focus is on an optimized operating strategy with transient load profiles, which should, for example, enable grid utility. In addition, PHOENIX enables the coupling of technologies in order to research and further develop future sector coupling concepts.

PHOENIX's open innovation approach enables extensive cooperation with leading industrial partners to de-risk pre-commercial demonstrators, such as bi-directional charging in the vehicle-to-grid approach or the transient operation of megawatt-class electrolyzers, in order to complete the technology transfer to industrial application.

Modelling and Analytic Space - SMART (Simulation, Modeling & Advanced Reliability Testing)

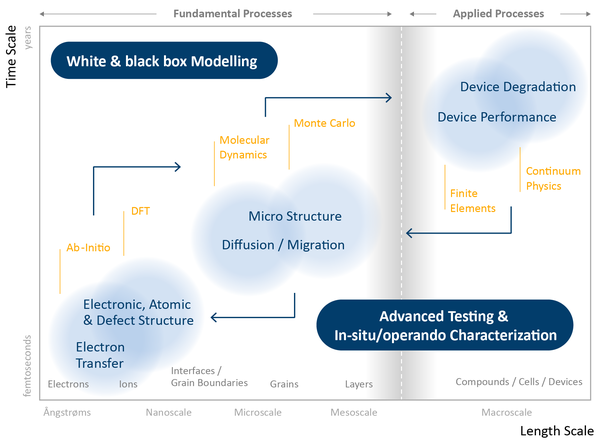

At every level of LAB2FAB, advanced in-situ / operando analysis and characterization of the complex electrochemical mechanisms play a crucial role. Our knowledge-based research approach is based on the premise that by understanding the detailed structures and individual processes, we can improve the systems and their properties more specifically and effectively. At IET-1, we have a variety of state-of-the-art analysis and characterization techniques at our disposal, as well as experts who develop special, novel in-situ / operando methods in order to gain valuable, previously inaccessible knowledge about electrochemical systems.

In addition to our broad expertise in a wide variety of experimental techniques, theoretical simulation and computer-aided modeling also play an important role. Using a wide range of methods from ab-initio calculations to physical models and machine learning, we pursue a multi-scale approach to theoretical description in order to be able to describe electrochemical systems from single ions to stacks and from picoseconds to several years. These models can be used to create so-called digital twins, which are computer-based models that can monitor an electrochemical system, diagnose its condition and predict its response to changes. Ultimately, this information from analytics, characterization, and modeling provides valuable insights for optimizing materials, components, and cells in every step along the LAB2FAB process, thereby supporting an accelerated innovation cycle.