X-ray Computed Tomography

The XCT Team is focusing on in-operando screening of energy materials and systems. This includes electrolyzers, conventional lithium-ion batteries as well as novel alternatives, such as zinc-air, or iron-air batteries. By image analysis of acquired, evolving morphology, degradation mechanisms are unveiled leading to better performance or practicality (e.g. higher cyclability of metal-air cells). Special attention is given to method development, i.e. custom measurement protocols, and cell design.

X-ray computed tomography (XCT) is a non-destructive, three-dimensional imaging technique which is perfectly suited for material characterization 1. At IET-1, both energy storage and conversion systems are being investigated with the help of XCT. The individual components as well as complete cells can be screened ex-situ, post-mortem or in-operando. Special cells are being developed actively, mimicking the large-scale, real systems, and allowing to assess dynamics of the processes driving the evolution of observed morphology. From water electrolysis, through CO2 reduction to development of novel batteries – XCT offers high spatial and (with help of compressed sensing) temporal resolution. Correlative imaging at IET-1 combines state-of-the-art micro-CT, namely XRADIA Versa 620 with high resolution nano-CT, i.e. XRADIA Ultra 810, giving nano-meter range resolving power without compromising the field of view.

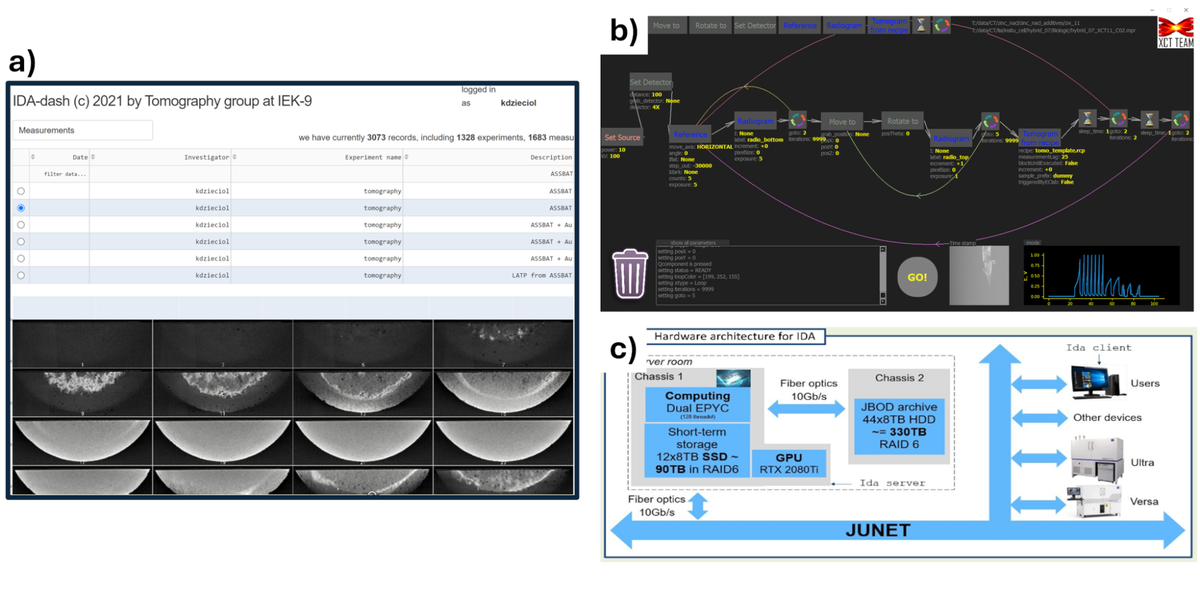

Custom Measurement Protocols and Hardware Infrastructure

Custom measurement protocols allow in-operando multi-scale studies by fusing radiograms with tomograms at different magnifications to benefit from both – high spatial and temporal resolution. Special software was developed in-house, allowing us to design unique measurement sequences and ensure synchronization between imaging and electrochemical cycling. Since in-operando measurements generate enormous amount of data, this software is bound with adequate infrastructure facilitating 300 TB of archive storage and nearly 100 TB of ultra-fast SSD RAID attached to AMD EPYC platform. An efficient and highly scalable graph-database was designed specifically to allow convenient download and remote browsing of imaging data using simplistic Python and/or Matlab scripts.

Examples of in-operando Studies

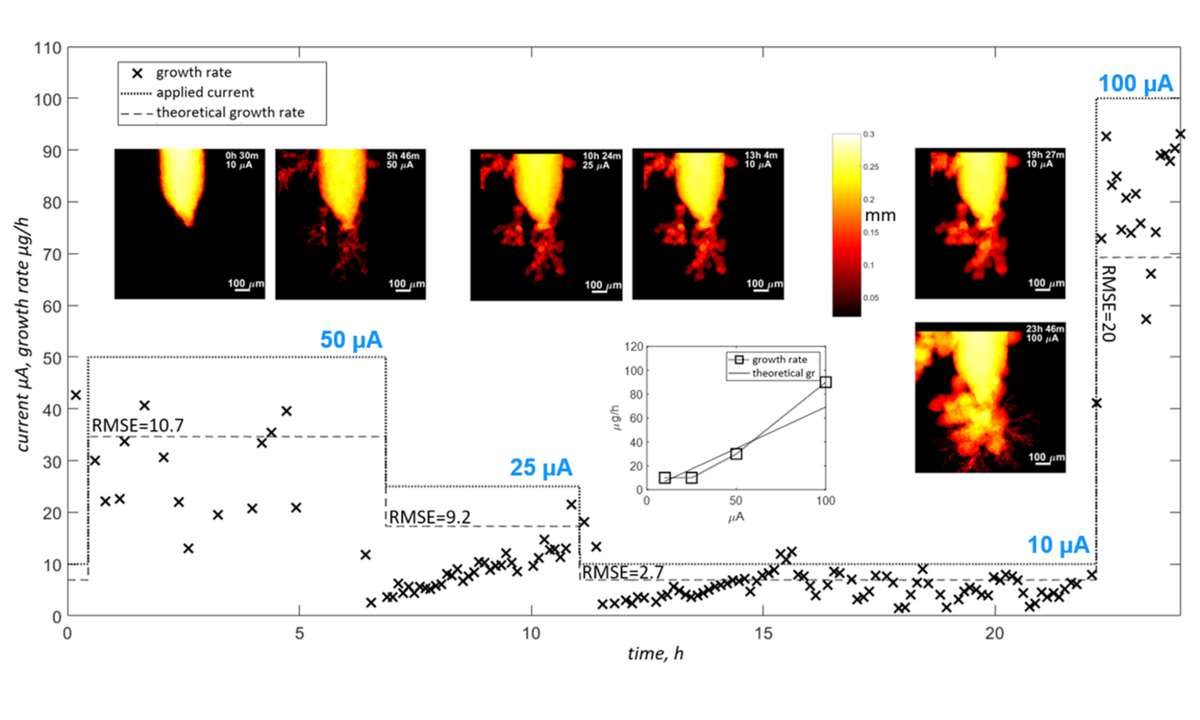

A typical application of the IET-1 imaging infrastructure is the investigation of dendrites formation in specific conditions defined by chemical composition of electrolyte and the used electrode material 3 . Dendrites, which can appear in many types of batteries, are the effect of inhomogeneous deposition of active material during charging and lead to short-circuits and in consequence to premature failure of the system. Understanding dendrite formation is the key for developing reliable secondary batteries especially in “beyond-lithium” systems like metal-air. Here, it was shown that fast radiography can be extrapolated to three-dimensional growth-rates enabling the use of laboratory XCT for in-operando testing of material plating/stripping during charge/discharge. It is important, since typically synchrotron radiation is utilized, which is not cost and time efficient solution and most importantly not easily accessible.

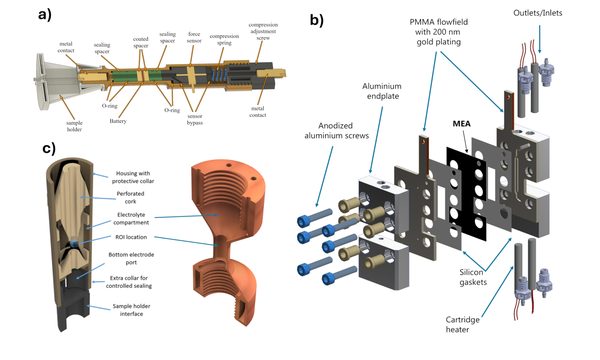

This type of study requires the development of specialized cells which are penetrable by X-rays while at the same time allowing normal operation during cycling. This is not a trivial task in case of air/water sensitive systems like e.g. all-solid state batteries. Recently, we developed a special in-situ cell for imaging air-sensitive materials operating under required pressure (patent pending). Here, we show some examples of cells developed at IET-1. Some of them were already used in published work – for example Schmidt et al. 4 , used customized cell to investigate anode-less lithium battery.

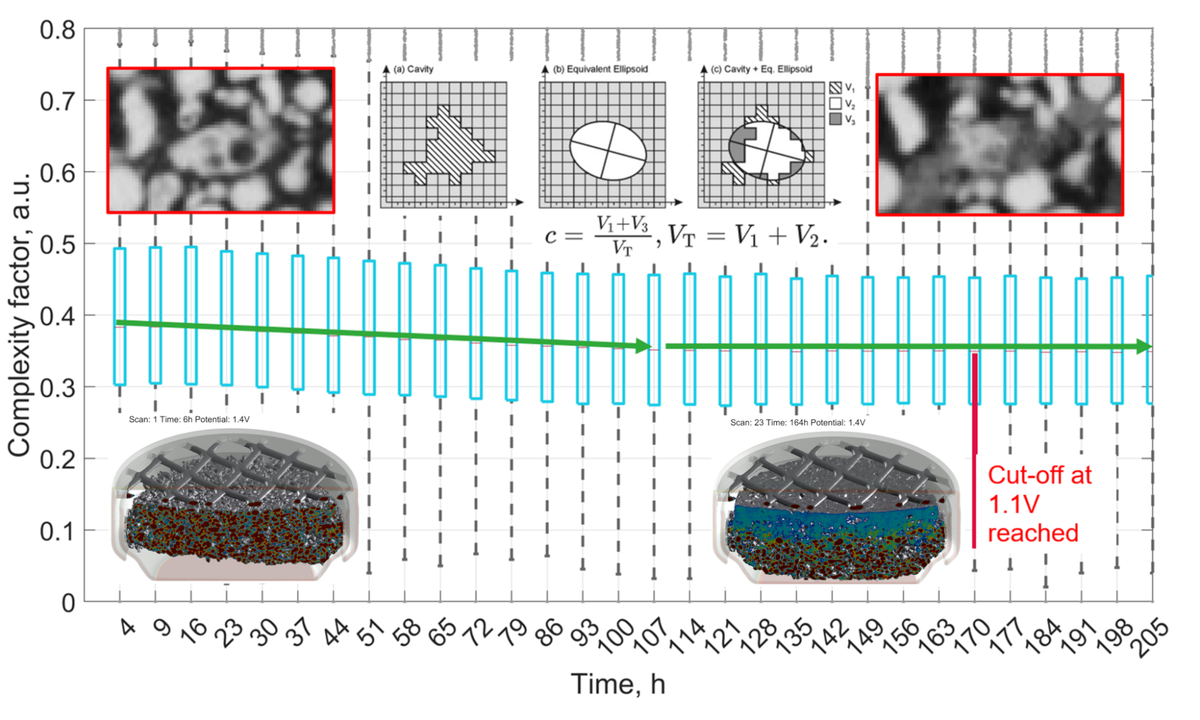

Not only are the fundamental phenomena within the scope of interest of XCT team. Commercial cells can be screened as well during normal operation. For instance, performance of typical hearing-aid battery utilizing environmentally friendly material, namely – zinc, can be linked with morphological changes within the anode. The discharge down to typical cut-off potential (1.1 V) revealed that around 50% of the active material was still not used. At the same time, morphological descriptors showed that more complex surface topology of zinc particles can improve the utilization of the anode.

Further Work

Although observation of on-going process is of highest interest, post-mortem and ex-situ examination often provide sufficient information to understand underlying mechanisms of degradation. For example, Heume et al., 5 brought attention to previously unknown phenomenon hindering the performance of polymer electrolyte water electrolyzers due to specific design/choice of gas diffusion electrodes. Kaltenberg et al., linked the morphological changes observed by CT with current collector design in iron anode. On the other hand, Wehner et al. 7 , compared high-resolution metallographic technique, namely FIB/SEM to nano-XCT in terms of detectable porosity and tortuosity values. Finally, by observing the porosity of 3D printed metals, Jaskari et al. 8 , could speculate about optimal energy density for laser beam powder bed fusion process.