Materials Development

Our current research focus is on the development of alternative electrode materials with high electrochemical performance and long-term stability for both solid oxide and solid proton conducting cells (SOCs, SPCC). With respect to alternative fuel electrodes for SOCs, our current materials of interest are Ni-GDC, Sr2Fe2-xMoxMO6-δ (M=Ni, Co, Mn, Cu, Ti), (La,Sr)(Cr,Fe)O3 and doped ceria based materials. Concerning the oxygen electrode, we are particularly interested in Ruddlesden-Popper nickelates, e.g. Ln2NiO4+δ or Ln4Ni3O10±δ (Ln = La, Pr or Nd), as well as substitutions in these nickelates at the A- and B-sites by other elements.

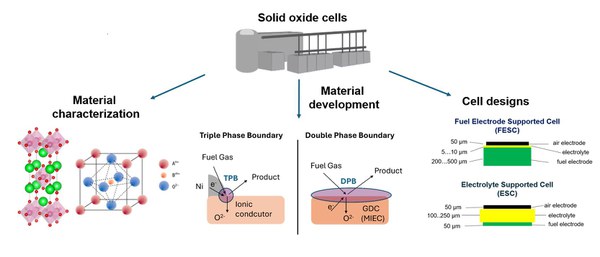

The core area of our research is the advancement of solid oxide cells (SOCs) through the development of novel materials. One of the key challenges, especially in the development of solid oxide electrolysis cells (SOEC), is the stability of the electrodes 1 . The state-of-the-art Ni-YSZ fuel electrode exhibits significant degradation due to Ni-migration away from the electrolyte/electrode interface and its agglomeration. The Ni-GDC as an alternative fuel electrode shows higher performance than the Ni-YSZ cell due to mixed ionic and electronic conductivity of the GDC. However, it still shows Ni-migration and agglomeration 2, 3 .

Double perovskite materials are promising alternative fuel electrode materials due to their mixed ionic and electronic conducting properties. Especially in combination with GDC, the composite electrode shows stable behavior during high temperature electrolysis operation 1 .

Doped ceria-based materials such as Gd doped ceria are another promising fuel electrode materials for SOECs 1, 2. The doped ceria-based materials are interesting because of mixed ionic and electronic conductivity under reducing atmosphere. They show similar performance to the Ni-YSZ electrode 3 .

With respect to the oxygen electrode, the state-of-the-art LSCF electrode shows Sr-segregation during long-term operation under SOEC conditions. Materials based on Ruddlesden-popper nickelates are promising alternative oxygen electrode materials due to their high oxygen diffusion and surface exchange properties compared to materials based on perovskites such as LSCF. Further substitution at Ni-sites with Co greatly improves the electrochemical performance and also leads to stable cell performance 1, 2 .

In addition to oxide ion-conducting SOCs, we are also developing solid proton-conducting cells that can operate in both fuel cell and electrolysis modes. Recently, we have successfully demonstrated the electrolyte and fuel electrode supported proton conducting single cells using BCZYYb electrolyte, Ni-BZY or Ni-BCZYYb fuel electrode and Pr2NiO4+δ or BSCF oxygen electrode 1 . Currently, the focus is also on the development of novel high performance oxygen electrode materials that are stable under operating conditions, especially under electrolysis conditions with high steam content.

Our interest also focuses on the development of direct ammonia fuel cells using both solid oxide and solid proton conducting fuel cells (SOFC, SPCFC), as ammonia is a potential future energy carrier and can reduce the challenges of hydrogen transportation, hydrogen storage and hydrogen safety 1 .

In summary, our current work involves the development of novel materials through solid-state synthesis or wet chemical processes. Further optimization of various materials using materials engineering strategies are in progress. Several techniques are used to characterize the materials such as XRD, DSC-TGA, dilatometry, and four probe conductivity, SEM-EDX, HR-TEM, and XPS. After processing the materials, the cells are manufactured using die pressing, cold isostatic pressing, tape casting and screen printing techniques. Finally, the electrochemical measurements and the investigation of the long-term stability of the fabricated cells are carried out under fuel cell or electrolysis conditions. We also further optimize the cell by adapting different cell geometries.