High-Voltage Cathode Materials for Lithium-Ion Batteries

As technology advances and the political support for electric vehicles increases, lithium-ion batteries (LIBs) will become more and more important. To reduce environmental pollution and mitigate the energy crisis, it is necessary to further develop technology in the battery sector. In this context, high-voltage cathode materials for lithium-ion batteries are a key factor since they have a very high energy and power density. A suitable material for high-voltage cathodes in LIBs is, for example, LiNi0.5Mn1.5O4 (LNMO). LNMO is a spinel, which shows an oxidation plateau of ~4.7 V vs. Li/Li+, is cheap to produce, and has a specific capacity of 147 mAh/g as well as a high power density. However, there are some challenges that have yet to be resolved before LNMO can be used as a cathode material in commercial batteries. One issue is the low durability and cycle stability compared to other cathode materials such as LiNixMnyCozO2 (NMC) or LiFePO4 (LFP), which still have over 80 % of their initial capacity after approximately 5000 cycles.

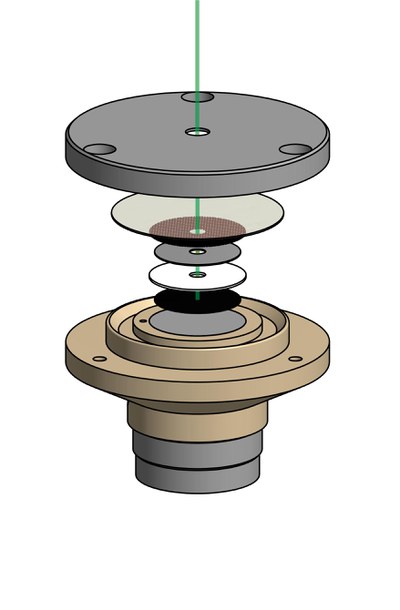

Our research into LNMO aims to gain an understanding of the fundamental chemistry and structural changes during the charging and discharging process. We use analysis techniques such as electrochemical energy impedance spectroscopy, Raman spectroscopy, secondary ion mass spectrometry, and X-ray diffractometry. In addition to ex situ studies on cathodes, we also conduct in operando measurements using optical battery cells (see Figure 1). During these measurements, the cathode is electrochemically cyclized and simultaneously investigated using Raman spectroscopy. This technique makes it possible to measure the structural change in the cathode material simultaneously with the potential, which helps to provide a better understanding of the mechanisms involved. The optical measuring cell is set up as follows (from bottom to top): cathode material on aluminium film, separator, metallic lithium on expanded metal, and sapphire glass.

In addition to the structural change of the active material, we investigate whether a top layer forms on the cathode surface, thus causing an ion blockade. It is assumed that cathode top layers form at high oxidation potentials, which have so far only been found on the anode side.