Low-temperature electrolysis (VEL & EEL)

The low temperature electrolysis (e.g. alkaline or PEM water electrolysis) enables high-performance, compact hydrogen production, which can be combined with suitable storage systems. This process is a key technology that contributes to the realization of an environmentally friendly, reliable and affordable energy supply for the future.

In alkaline water electrolysis, potassium hydroxide is used as the electrolyte solution. Furthermore, precious metals are not used as catalyst material. PEM electrolysis, on the other hand, uses a proton-conducting membrane as the electrolyte and its system configuration is comparatively simple.

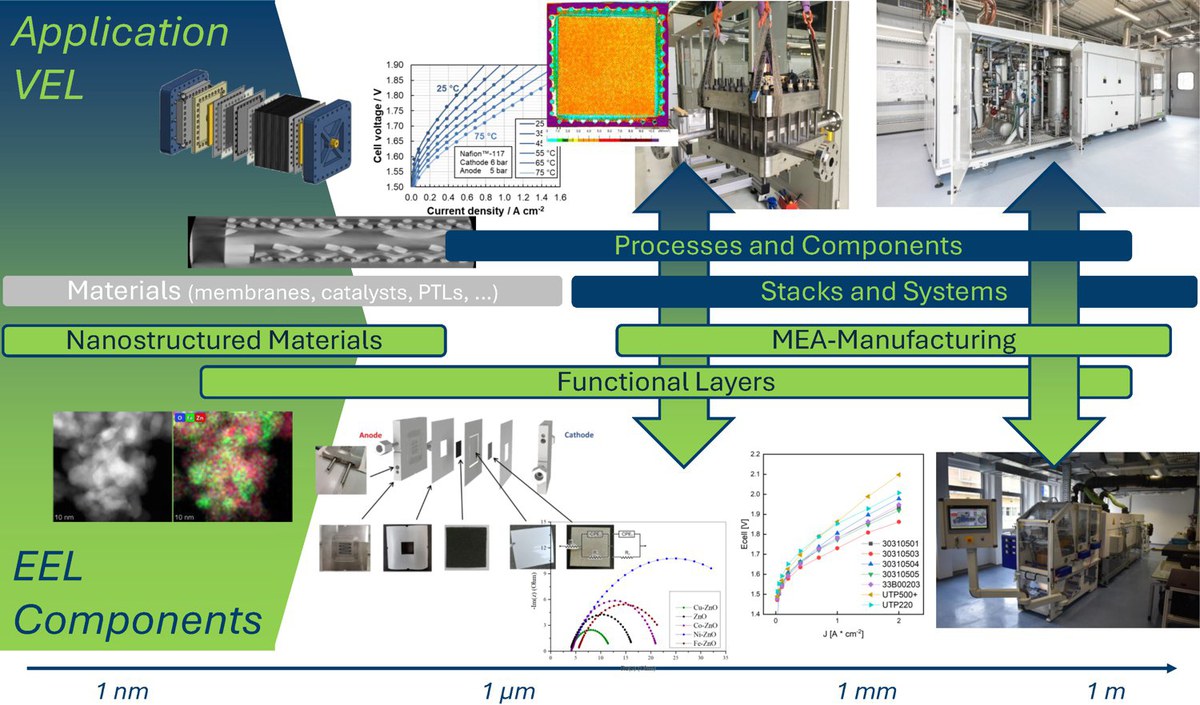

The scientists in the Electrochemistry Electrolysis (EEL) and Process Engineering Electrolysis (VEL) departments are investigating electrolysis technology at various stages of development and system sizes. This includes research and development on alkaline electrolysis, PEM electrolysis and alkaline PEM electrolysis. The focus of all activities is on increasing efficiency and improving the long-term stability of the components used. The following competencies provide the key to further development and are applied within the departments.

Functional Layer Systems

We develop and manufacture technical electrodes with innovative catalysts and ionomers for various applications. Our expertise includes dynamic mechanical analysis, measurements of electronic layer conductivity, and the development of automated test stands for electrochemical testing. Additionally, we conduct long-term investigations of water electrolysis cells and integrate our results into techno-economic models to optimize development paths.

MEA-Manufacturing

We focus on the development of scalable methods to produce efficient MEAs for safe stack operation. The physico-chemical processes inside the MEA need to be well adjusted by optimizing the materials and production processes used for MEA preparation. The different process steps are developed and optimized on laboratory scale and are later scaled up to pilot plant scale.

Processes and Components

We develop and characterize new components and electrochemical processes at the single-cell scale. For this purpose, we develop new characterization methods and cell designs. Special focus is on new modes of operation and dynamic operation with renewable energies.

Stacks and Systems

We develop and test components, cells, stacks and systems for low-temperature water electrolysis. We use modelling tools (flow, electrochemistry and mechanics) and test rigs for short and long-term characterization. The work addresses PEM, AEL and AEM electrolysis.

Team EEL & VEL

Head of departments

Process Engineering Electrolysis Dr. Martin Müller

Electrochemistry Electrolysis Prof. Anna Mechler