Scalable MEA Production

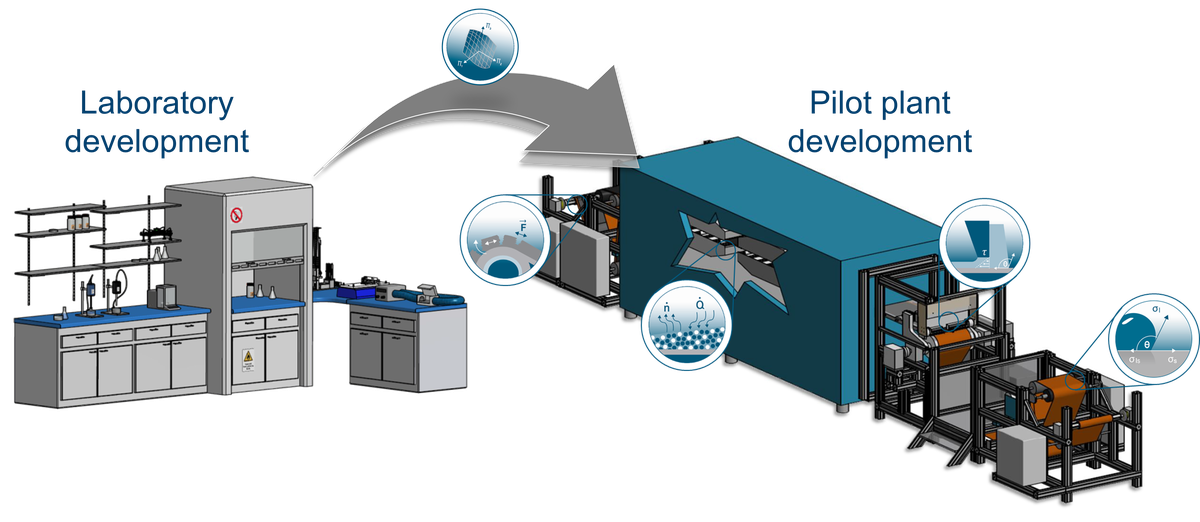

The laboratory development needs to be conducted with regard to efficient and scalable processes. Not all laboratory processes are scalable. For this purpose, suitable methods must be used and developed that can be seamlessly transferred from the laboratory to the pilot and industrial plant scale.

The development of methods for the production of functional layer systems (membrane electrode assemblies MEA) is usually initially carried out on a laboratory scale. New ideas and processes can thus be tested with small quantities of material in the gram or millilitre range. If a method proves to be promising, material quantities up to the kilogram range are required for larger trials, so-called pilot plant tests. It often turns out that the laboratory methods cannot be used for these tests because the materials show different behaviour. For example, a dispersion of catalyst and solvent produced in the laboratory can be processed into a square-centimeter-sized layer in a few minutes, whereas the production of square-meter-sized layers can take well over an hour. So production in the lab is on different time scales compared to production in a pilot plant. A dispersion that is stable for only 10 minutes may be suitable for the laboratory procedure, but not for the larger batch. The adaptation of MEA production processes to larger scales (time and space) is the subject of scale-up, which is carried out at IET-4 for the production of polymer electrolyte electrolysers and fuel cells, among other things.

Therefore laboratory and pilot plant processes have to be analyzed and scale-up rules have to be found.

Correlation between process parameters and MEA properties

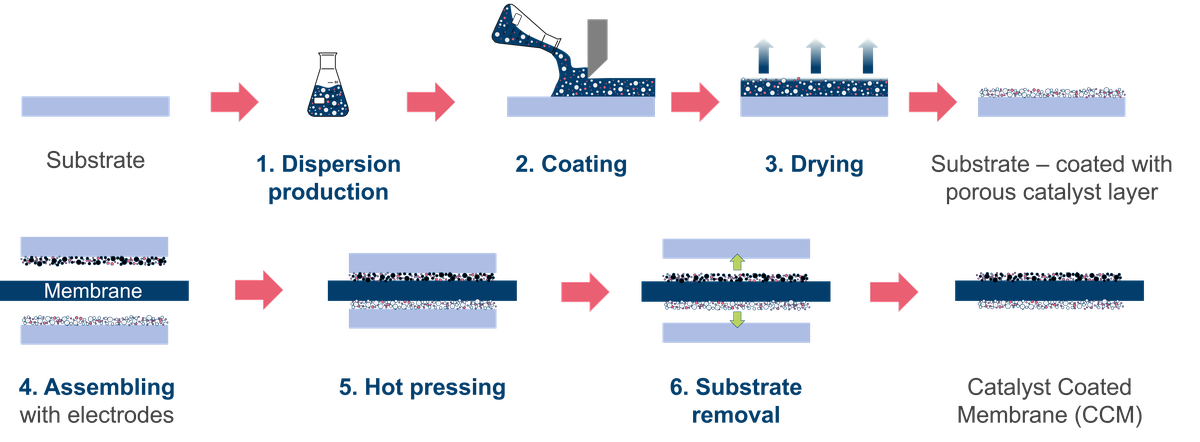

For scale transfer, knowledge of the correlation between material, process and performance parameters of the produced MEA is required. For the identification of the scaling rules, it must be known which of these parameters influence the MEA performance and which do not. For this purpose, a comprehensive process analysis is being developed at IET-4, which focuses on the following process steps:

Highly efficient and scalable production methods

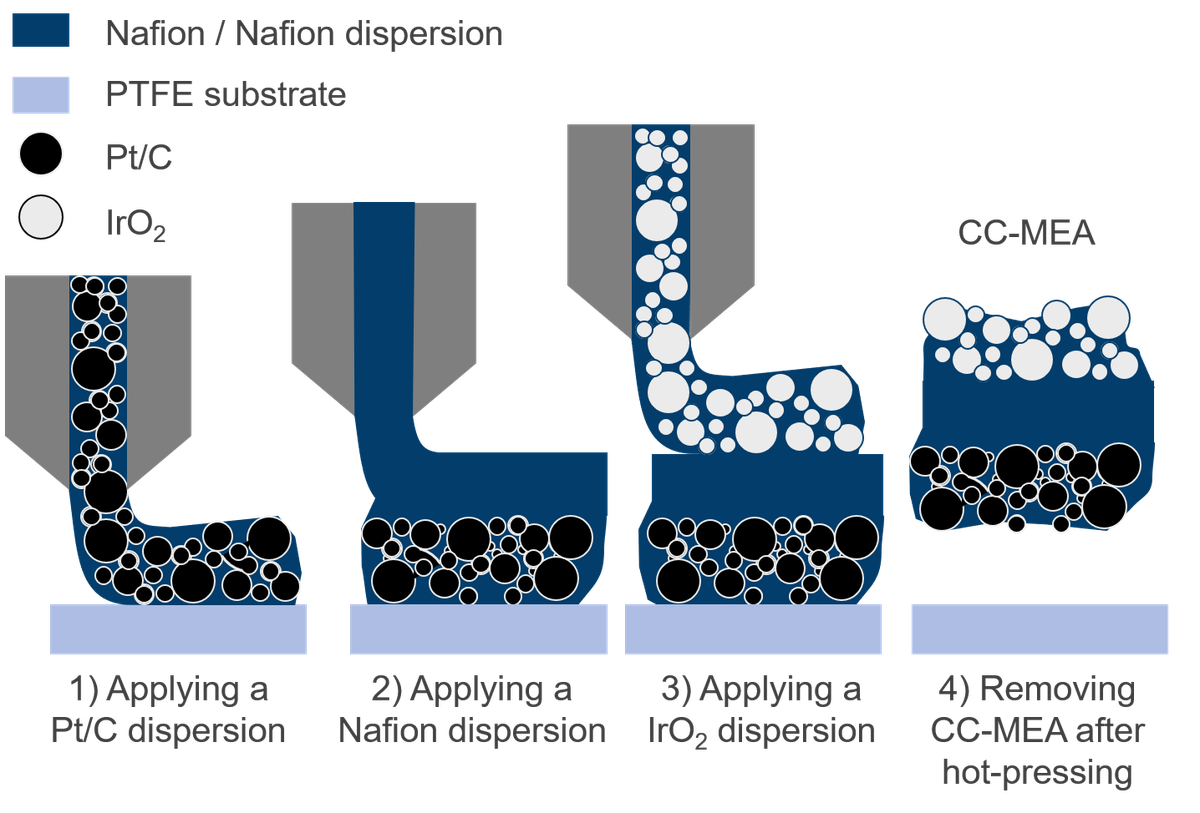

Understanding structure formation processes is the key to identifying scale-up rules. This permits the transfer of the results from laboratory development to large-scale production. Furthermore, these insights are used to develop new fabrication methods to make the production of MEAs simpler, faster, and therefore cheaper. For example, an MEA fabrication method was developed at IET-4 that requires fewer process steps than conventional production methods while at the same time producing less waste. This “completely coated MEA” (CC-MEA) method involves producing the two electrode layers and the membrane solely via slot-die processes, which dispenses with the need for a separate membrane and the assembly step.

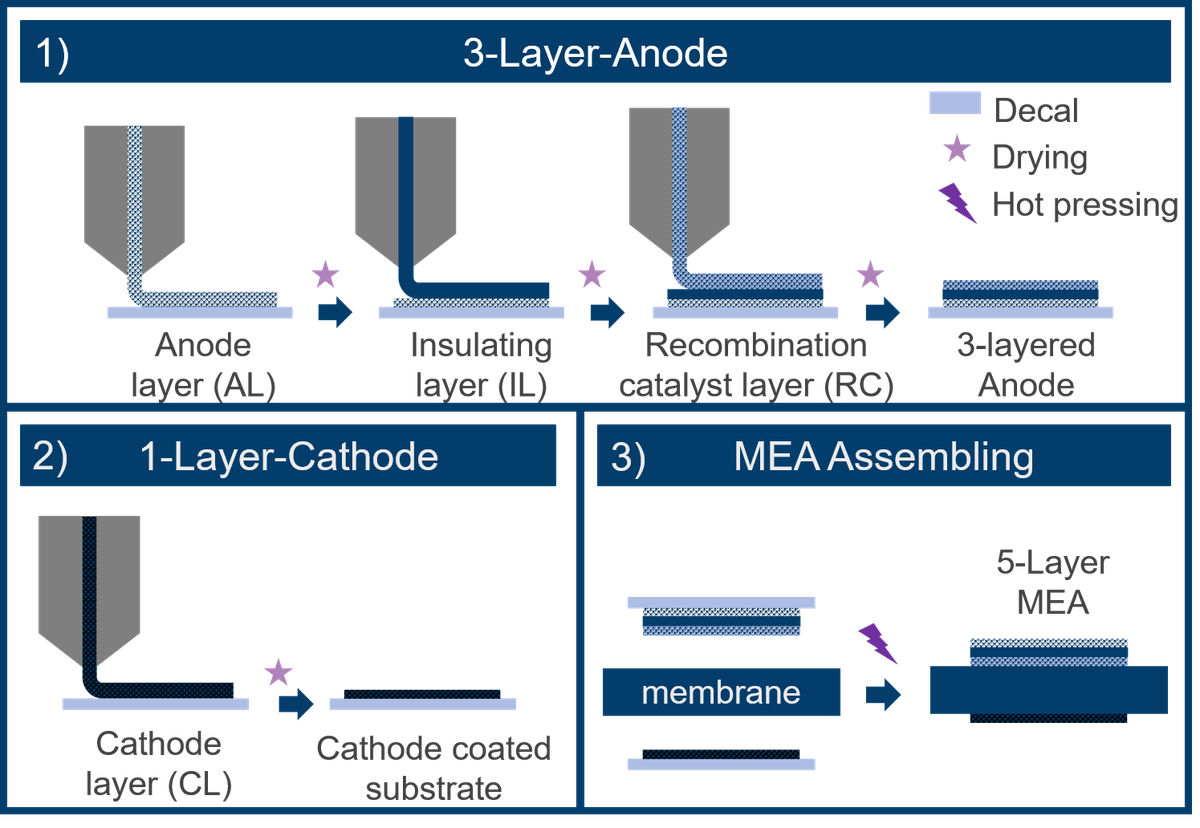

Scalable implementation of recombination catalyst

For the production of MEAs with implemented catalyst layers a scalable production method is needed. Slot die coating is a suitable method for this, which can be implemented in processes with high speeds and large widths. The IET-4 uses an MEA manufacturing process in which a 3-layer anode is produced through three subsequent coating steps. The anode is covered with an insulating ionomer layer and an ionomer layer containing a recombination catalyst, dried and pressed onto a commercially available membrane with a single-layer cathode using the hot-pressing process. The resulting 5-layer MEA can be used for safe operation of a cell or stack.