Key Component for Industrial Synthesis of Methanol Identified

31 May 2021

Methanol can be used as an energy source or as a raw material for the production of other chemicals. This alcohol is one of the most commonly produced organic chemicals – over 60 million tonnes of the liquid are produced every year, usually by means of a catalytic process. A team of researchers in collaboration with the Ernst Ruska-Centre for Microscopy and Spectroscopy with Electrons (ER-C) has now presented new findings on the chemical processes during catalysis and new approaches for its optimization.

The current commercial production of methanol through the hydrogenation of the green-house gas CO2 relies on a catalyst consisting of copper, zinc oxide and aluminium oxide. Even though this catalyst has been used for several decades in the chemical industry, there are still many unanswered questions surrounding it. A team of researchers led by the Fritz Haber Institute (FHI) of the Max Planck Society have now identified the origin of the intriguing catalytic activity and selectivity trends of complex nanocatalysts during the reaction. In particular, they shed light on the role of the oxidic support material and revealed how methanol production can be influenced by minute amounts of zinc oxide in close contact with copper.

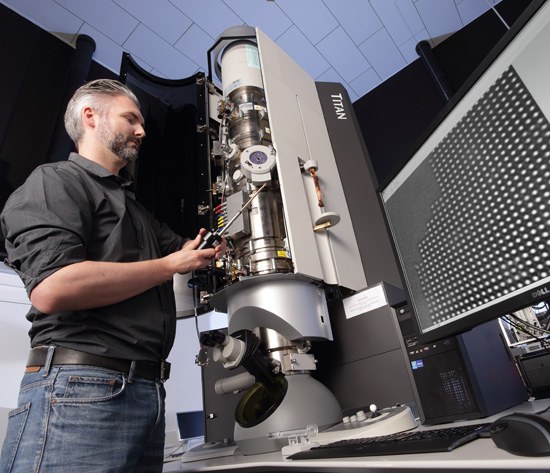

The team investigated the catalytic process under realistic reaction conditions reproducing those applied in the industrial process, meaning high pressures (20-60 bar) and low temperatures. To characterize the microstructure and elemental distribution of copper and zinc within the nanocatalysts, the samples were studied using high-resolution probe-corrected scanning transmission electron microscopy and X-ray spectroscopy on a TITAN microscope at the ER-C.

In addition to the ER-C and the FHI, the Ruhr Universität Bochum (RUB), as well as the National Accelerator Laboratory of the Stanford Linear Accelerator (SLAC) and the Brookhaven National Laboratory in the USA took part in the research project.

By combining results from microscopy, spectroscopy and catalytic measurements, the team found that some supports had a more positive influence on the performance of the catalyst than others because of how they interacted with zinc oxide, which was available in a highly diluted form as part of the Cu-Zn nanoparticles. On silicon oxide supports, zinc oxide was partially reduced to metallic zinc or gave rise to a brass alloy during the catalytic process, which over time proved to be detrimental for methanol production. When using aluminium oxide as a support, zinc interacts strongly with the support and is incorporated into its lattice, leading to a change in reaction selectivity towards dimethyl ether.

This study demonstrates that zinc oxide does not need to be available as part of the support, but that it still has a beneficial function even when present in a highly diluted form as part of the nanoparticle catalyst itself. This may help to better understand the methanol synthesis catalysts and potentially lead to an improvement of the catalyst for this important industrial process.

Further information:

FHI press release “

Zinc oxide: key component for the methanol synthesis reaction over copper catalysts

” published on March 4, 2021Original publication:

Núria J. Divins et al.;

Operando High-Pressure investigation of Size-Controlled CuZn Catalysts for the Methanol Synthesis Reaction

Nature Communications, March 2021, DOI: 10.1038/s41467-021-21604-7.