Equipment for heat treatment

The IMD-2 has 38 chamber furnaces available for heat treatment. The majority of the furnaces are designed for heat treatment in air, but processing can also be carried out in pure oxygen, nitrogen, argon, argon-hydrogen, or in a vacuum. This means that after shaping, not only can the structure of materials be optimized in terms of density, particle size, and morphology, but solid-state reactions or phase transformations can also be carried out.

• Maximum temperatures: 1100-1800°C

• Usable volume: 3-200 Liter

Field assisted sintering technology/spark plasma sintering (FAST/SPS)

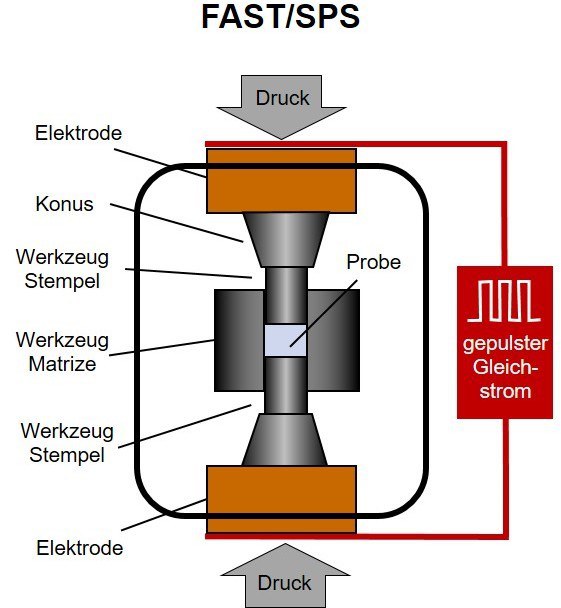

Field assisted sintering (FAST/SPS) is a low-voltage, current- and pressure-assisted sintering process based on Joule heating (= resistance heating) of a conductive tool. When electrically conductive powders are compacted, the powder is also heated directly via the Joule effect. The tool consists of two punches and a die into which the powder to be sintered is filled. Specific advantages of FAST/SPS technology are high heating rates and short cycle times. The process is carried out under protective gas or in a vacuum. The following figure shows the basic design of a FAST/SPS system and the tool in its heated state.

Three FAST/SPS systems are operated at the IMD-2 institute (see below). The HP-D5 system from FCT Systeme GmbH is a standard laboratory-scale FAST/SPS system that is used in a variety of ways at the IMD-2 institute for sintering ceramic and metallic powders. The H-HP-D25 system from FCT Systeme GmbH is a hybrid FAST/SPS system in which an additional furnace (induction furnace or MoSi2 furnace) can be installed to increase the heat input and achieve a more homogeneous temperature distribution. Furthermore, the system has an external voltage source that enables sintering processes with extremely high heating rates – flash sintering (FS) and ultra-fast high-temperature sintering (UHS) – to be carried out in the system. The DSP515 system from Dr. Fritsch Sondermaschinen GmbH is a prototype-scale FAST/SPS system that aims to scale the FAST/SPS process for industrial application. The right-hand column in the following figure summarizes the key operating parameters of the three systems.

Operating parameters HP-D5::

• Max. load 50 kN

• Max. heating power 37 kW

• Max. sample size ⌀ 30 mm

• Max. temperature 2200°C (with graphite tools)

• Sintering atmospheres: Vacuum, Ar, Ar/H2, air

Operating modes:

• FAST/SPS (pulsed direct current)

• High pressure FAST/PLC (up to 1 GPa)

• Cold sintering in the temperature range 100 – 400°C

Operating parameters H-HP-D25:

• Max. load 250 kN

• Max. sample size ⌀ 100 mm

• Max. heating power 60 kW for FAST/SPS operation

• Max. heating power 80 kW for hybrid heating

• Max. temperature 2200°C (with graphite tools)

• External voltage source (max. 1000 V, max. 25 A)

• Sintering atmospheres: Vacuum, Ar, Ar/H2, air

Operating modes:

• FAST/SPS (pulsed direct current)

• Hybrid FAST/SPS (Induction or MoSi2 furnace)

• Flash sintering FS

• Ultra-fast high-temperature sintering UHS

Operating parameters DSP515:

• Max. load 555 kN

• Max. sample size ⌀ 120 mm or 100 x 100 mm2

• Max. heating power 170 kW

• Max. temperature 2200°C (with graphite tools)

• Sintering atmospheres: Vacuum, Ar, Ar/H2, air

• Equipped with a cooling trap for debinding

• Temperature monitoring with up to 5 thermocouples

Operating modes:

• FAST/SPS (constant direct current)

Sinter Forging Equipment

The institute operates a unique, self-designed sinter forging system. The components of the system are a vertical sintering furnace for temperatures up to 1300°C, a voltage source (AC and DC, max. 1000 V, max. 20 A), an electromechanical tensile-compression testing unit (Instron, Norwood/US), and two optical lasers. The plant can be used to determine important parameters for modeling sintering processes (viscosity, Poisson's ratio, sintering stress) under pressure load using optical dilatometry. Cylinders with a diameter ≤ 10 mm are used as samples, which are contacted via Pt electrodes and subjected to pressure via the plant's stamps.