Equipment for analysis

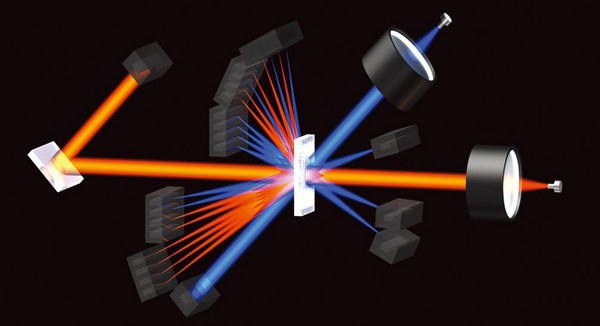

Particle size measurement using laser light

The measurement of particle sizes using laser scattering is a standard method based on the scattering of light by particles. A fundamental distinction is made between static and dynamic laser diffraction, also known as static and dynamic light scattering (SLS and DLS).

Static laser diffraction

In static laser diffraction or static laser scattering (SLS), a laser beam is passed through a suspension or mist of particles. The particles scatter the light in different directions, with the scattering angle depending on the particle size: large particles tend to scatter at small angles (close to the forward direction), while small particles also scatter at larger angles. The resulting diffraction pattern—a characteristic intensity profile of the scattered radiation—is recorded with a detector ring. By applying optical models (e.g., Mie theory or Fraunhofer diffraction), the particle size distribution can be calculated from this pattern. Static laser diffraction is particularly suitable for particles in the size range from approx. 0.1 µm to several millimeters and allows the analysis of samples with a wide size distribution spectrum. In the case of partially transparent particles below a diameter of about 3-5 µm, not only the size but also the optical properties have a significant influence on the intensity profile.

Dynamic laser diffraction

Dynamic laser diffraction or dynamic light scattering (DLS) is based on the analysis of temporal fluctuations in scattering intensity caused by the Brownian motion of particles in a liquid. When a laser is directed at a suspension of very small particles (typically in the nanometer range), the particles move randomly all the time, resulting in characteristic fluctuations in the scattered light. These intensity fluctuations are measured with a highly sensitive detector, typically at a fixed scattering angle (e.g., 90°). The translational diffusion coefficient of the particles can be determined from the temporal autocorrelation function of these fluctuations. Using the Stokes-Einstein equation, the hydrodynamic diameter of the particles can be calculated from this, i.e., the effective diameter including any solvate shell that may be present.

Device: Horiba LB 550 (laser 650 nm, measuring range 1 nm – 6 µm, concentration range 10 ppm – 40 vol%, measuring volume 0.1 ml – 30 ml)

Mercury porosimetry

Intrusion of mercury into the open porosity of the test specimen as a function of pressure p. The Washburn equation is used to calculate the corresponding pore size D from the applied pressure.

D = - 4γ/p * cosθ

The pore volume is calculated from the intruded Hg volume.

Gas pycnometry

Gas pycnometers are based on the principle that the samples to be measured displace a test gas in a sample chamber with their volume. The difference in the volume of the test gas compared to the empty sample chamber or a reference chamber is measured. This allows the true density of powders and solids to be determined.

Gas absorption (BET) measurement

Gas absorption can be used to determine the surface area of fine-grained or porous solids using a so-called BET measurement.

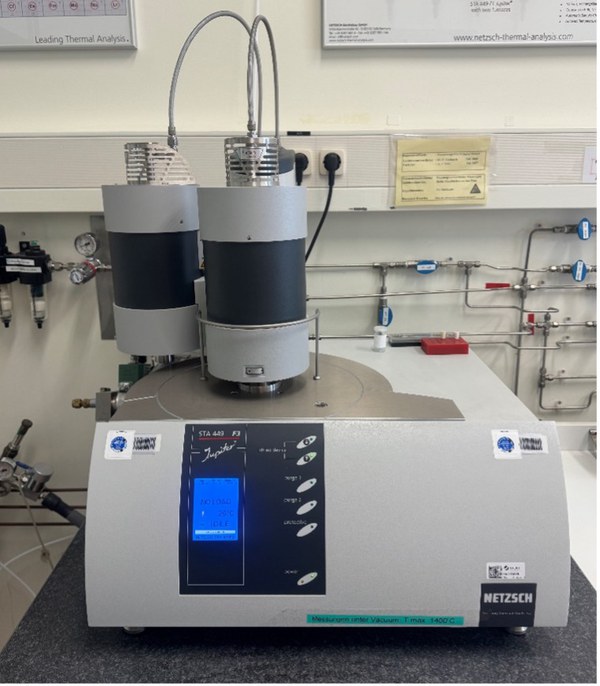

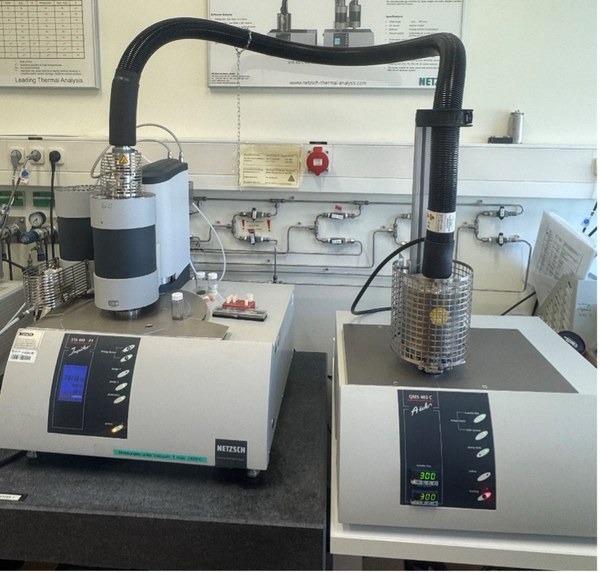

Thermoanalytical measurement methods

Differential thermal analysis (DTA) is a very effective method for determining specific material properties in order to characterize material properties. Not only can the mass change of a sample be determined as a function of temperature and time, but the energy supplied or the amount of heat in the material can also be measured simultaneously. The measurement is based on a comparison of the temperatures of the sample and an inert reference substance.

A method developed from DTA is differential scanning calorimetry (DSC). While DTA records the temperature difference between the two crucibles (sample and reference) is recorded as a function of the energy supplied or the temperature of the reference substance, DSC records the heat flow difference. This allows characteristic temperatures and calorific parameters, e.g., specific heat capacity (Cp values) and enthalpies, to be determined.

Devices and measurement options

Dilatometry

Dilatometry is a technique in which a change in the length of a sample is measured, e.g., as a function of temperature, time, or oxygen partial pressure, while the material is subjected to a controlled temperature program in a specific atmosphere. In existing push rod dilatometers, the change in length is recorded using a rod that transmits the change in displacement of the sample for measurement. Since the measuring system is also exposed to the same temperature as the sample and therefore also expands, this is not a direct measurement, but rather a relative value that must then be corrected using standard reference values. This is particularly necessary when measuring small changes in length, e.g., when measuring thermal expansion. Furthermore, shrinkage, softening points, glass transition temperatures, phase transitions, melting points, influences of additives and raw materials, decomposition temperatures of e.g. organic binders, and optimizations of firing processes in reducing, oxidizing, or inert atmospheres can also be determined.

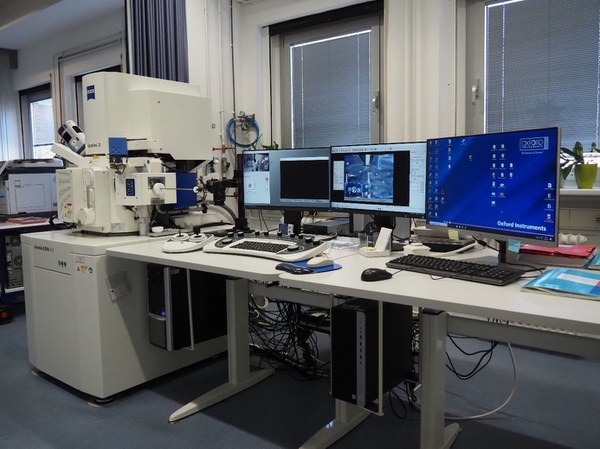

Scanning electron microscopy

The scanning electron microscope scans a sample surface line by line using a finely focused electron beam. The electron beam is generated either in so-called hot cathodes (tungsten hairpin cathodes) or in field emission cathodes. The electron beam acceleration voltage is between 200V and 30kV.

The interactions of the electrons with the sample are used to generate images, i.e., a corresponding detector is required for each signal emitted by the sample. For example, secondary electrons (SE) are produced after the electron beam interacts with the sample surface. They have very low energy and can be detected using an Everhart-Thornley detector or an InLens detector. The SE are used to image the surface topography.

The backscattered electrons (RE) originating from a larger sample volume provide initial chemical information on phase distributions in the sample, as they show the material contrast depending on the average atomic number. These primary electrons backscattered from the sample are more energetic than secondary electrons and have a typical energy of several keV.

Energy dispersive X-ray spectroscopy (EDS):

When scanning the sample with an electron beam, characteristic X-rays are also generated, which can be analyzed in an EDS detector.

EBSD (Electron Back Scatter Diffraction):

Electron back scatter diffraction can be used to detect the crystallographic orientation of crystals. The electrons reflected at the crystal surfaces of the sample are projected onto a detector screen and the resulting Kikuchi lines are analyzed.

Zeiss GeminiSEM 450: Thermal field emitter (Schottky emitter) with GEMINI II column, acceleration voltage: 0.02 - 30kV, sample current: 2pA – 40nA (stepless regulation), magnification: up to 2,000,000x based on Polaroid image format (4:3 format), sample lock, plasma cleaner for gentle removal of sample contamination

Detectors: Everhart-Thornley detector (topographical information) (SE); backscattered electron detector (BSE); InLens (SE) detector (high-resolution surface information); InLens EsB (RE) detector (material contrast); VPSE detector (secondary electron-like imaging in variable pressure mode, low vacuum); EDS system AZtec Live Advanced with ULTIM MAX 170 detector from Oxford Instruments; EBSD system AZtec with C-Nano from Oxford Instruments (crystal orientation). High vacuum.

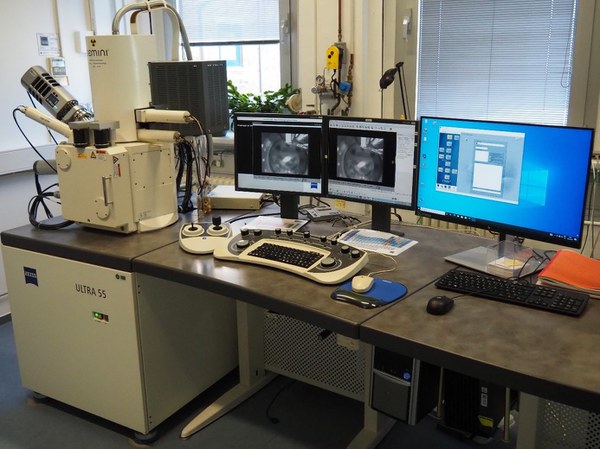

Zeiss Ultra 55: Thermal field emitter (Schottky emitter), acceleration voltage: 0.02 - 30 kV, fixed aperture diaphragms, magnification: up to 1,000,000 x based on Polaroid image format (4:3 format). Detectors: Everhart-Thornley detector (topographical information) (SE); backscattered electron detector (BSE); InLens (SE) detector (high-resolution surface information); InLens EsB (RE) detector (material contrast); EDS system INCA with X-Max 80mm2 from Oxford Instruments.

In cooperation with the Helmholtz Institute Münster (IMD-4), it is possible to analyze materials and components using a Helios 5 Laser PFIB scanning electron microscope (Thermo Scientific). This device allows samples to be prepared using laser cuts and a focused plasma beam (PFIB). Furthermore, the available cryo sample holder allows preparation and measurements to be carried out at low temperatures. This configuration also allows 3D tomographic imaging.

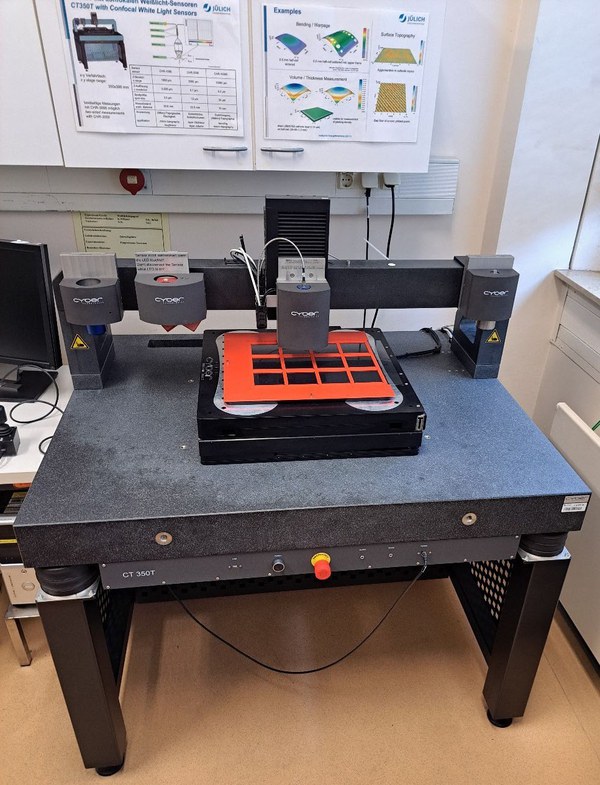

Confocal white light topography

Confocal white light sensors, which operate on the principle of chromatic aberration, can be used to measure surface topographies with high accuracy. The measurable height differences range from approx. 1 µm to 10 mm. Areas of application include the measurement of macroscopic deformation, layer thicknesses and volumes, microtopography, and roughness.

Double-sided measurements only with CHR-3000 and after production of a suitable mask.

Available sensors:

Confocal white light sensors

Model | Resolution [µm] | Measuring range [µm] |

|---|---|---|

CHR-1000 | 0,035 | 1000 |

CHR-3000 | 0,10 | 3000 |

CHR-10000 | 0,30 | 10000 |

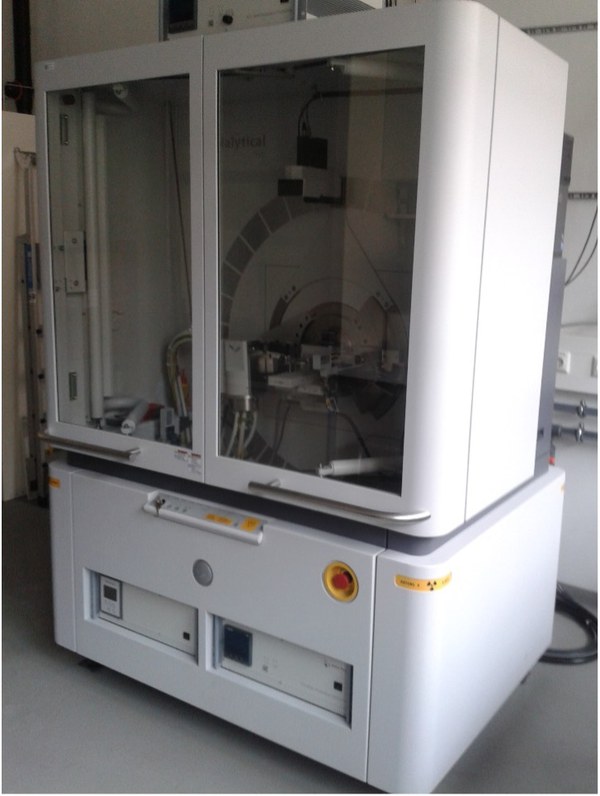

X-ray powder diffraction (XRPD)

Principle

In X-ray powder diffraction (XRPD), samples are examined using monochromatic X-rays. Typical applications include qualitative and quantitative phase identification. In addition, the lattice parameters, atomic positions, and crystallite sizes can be determined.

Services

- Qualitative/quantitative phase analysis of polycrystalline materials (deconvolution of superimposed interference patterns of complex phase mixtures, crystalline phases, X-ray amorphous components)

- Phase identification by search-match with the ICDD database (PDF-2 Release 2015)

- Determination and refinement of lattice parameters

- Refinement of crystal structures using Rietveld analysis

- Determination of crystallite sizes and micro-stresses

- In-situ X-ray diffraction at high temperatures (T = RT-1600°C) in different atmospheres (inert, vacuum up to 10-4 mbar)

- Determination of (local) residual stresses in surfaces and layers (sin2(Psi) method in omega and psi geometry)

- Orientation determination, texture analysis

- Investigations on thin layers and coatings

Special Software

- Powder Diffraction File (ICDD PDF-2, Release 2015)

- Crystallography Open Database (COD, 02/2023)

- Inorganic Crystal Structure Database (ICSD, online)

- X'Pert Suite (Data Collector 4.3, HighScorePlus 4.9), StressPlus, Texture

- DiffracPlus Evaluation Package V14 (EVA, Search/Match, DQuant)

- Total Pattern Analysis Solution Software (Topas 4.2)

Glow discharge spectroscopy (GDOES) for elemental analysis

A glow discharge is ignited on a small, superficial area of a sample, and, similar to sputtering, material is removed from the sample. The atoms in the glow plasma emit radiation characteristic of the atoms with a specific energy, which is detected and analyzed spectroscopically. The intensities of the characteristic radiation allow conclusions to be drawn about the amount of material in the plasma and thus in the sample. In this way, the material composition of a sample can be measured with excellent depth resolution. The maximum depth to which a sample can be measured is in the order of 100 micrometers, within a few minutes.

The IMD-2 has a Profiler 2 GDOES system from the manufacturer HORIBA, together with an autosampling unit specially manufactured to the institute's specifications for analyzing large samples or arrangements of several samples with a maximum analyzable area of 150 mm × 150 mm. All elements of the periodic table can be detected.

Fourier transform infrared spectroscopy (FTIR)

FTIR spectroscopy enables the qualitative and quantitative analysis of organic and inorganic substances by measuring the absorption of infrared radiation in a wide wavelength range. The absorption of characteristic wavelengths excites molecular vibrations, which allow conclusions to be drawn about functional groups and bonding relationships. Areas of application include: identification of unknown substances, comparison and classification of substances (e.g., purity checks), or the investigation of chemical bonds and functional groups.

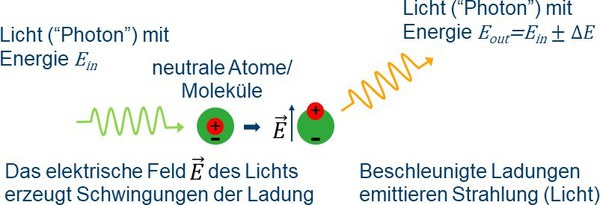

Raman spectroscopy for material determination

Light can be scattered by molecules and solids in such a way that the energy of the scattered light changes by certain energies ΔE.

The energy changes ΔE are determined by the chemical bonds of the individual atoms to their neighboring atoms and the resulting vibrations in the molecule or crystal lattice of the solid and are characteristic of a material.

Confocal Raman microscope InVia Qontor from RENISHAW. The highest possible spatial resolution is in the range of several hundred nanometers, and sample sizes up to 120 mm in lateral extent can be mapped using Raman spectroscopy. Together with a heating/cooling cell (manufacturer: Linkam), measurements from approximately -195 °C to 600 °C are possible. With a special optical measuring cell (manufacturer: EL-CELL) and a Biologic SP 300 impedance spectrometer, Raman measurements are performed on battery cells during charging and discharging processes.

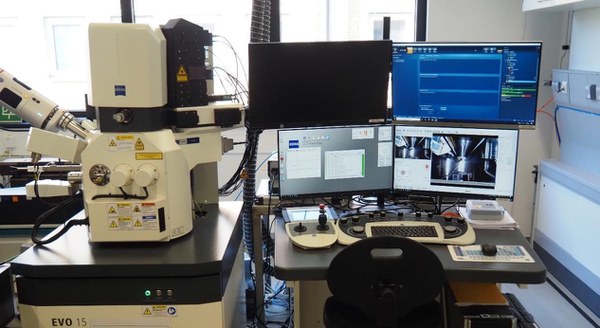

Scanning electron microscopy combined with Raman spectroscopy

The Zeiss Evo 15 scanning electron microscope (SEM) at IMD-2 allows high-resolution SEM images to be taken of a wide variety of sample systems.

In high vacuum mode (<10-5 mbar), an Everhart Thornley detector can be used to capture secondary electron images, which reflect the microstructure of the samples with high resolution. In addition, the SEM has another detector for backscattered electron images, which can provide an initial impression of the composition of the sample via what is known as material contrast. The actual element distribution in the sample system can also be examined using an Ultim Max EDS detector from Oxford with a sensor area of 100 mm2.

In addition to high vacuum mode, the Zeiss Evo SEM can also be operated in a variable pressure mode (up to 3000 Pa). In extended pressure mode, water vapor can be introduced into the chamber in a controlled manner in order to examine, for example, samples containing water or the formation of possible reaction layers in contact with water vapor on the sample surface. Using appropriate heating and cooling cells, the investigations can also be carried out at variable temperatures in the range from -25 °C to 1500 °C.

For correlative Raman Imaging and Scanning Electron (RISE) microscopy, the Evo 15 is also equipped with a confocal Raman microscope from Oxford/Witec. The Raman microscope is equipped with three lasers with wavelengths of 488, 532, and 633 nm. The laser beam is coupled into the sample chamber via an optical objective, which can scan a sample area of 250 µm x 250 µm and height differences up to 250 µm using piezo motors. This allows three-dimensional Raman mappings to be created, which can be directly correlated with the microstructure gained from the SEM images or the element distribution from the EDS measurements.

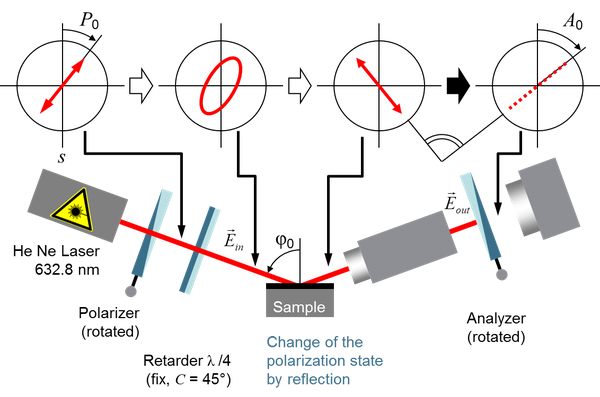

Laser ellipsometry

When elliptically polarized light hits a sample surface, its polarization direction changes according to Fresnel's formulas. If the refractive index of the material is known, measuring the change in polarization direction allows the thickness of a thin layer on a coated substrate (with a known refractive index) to be determined.

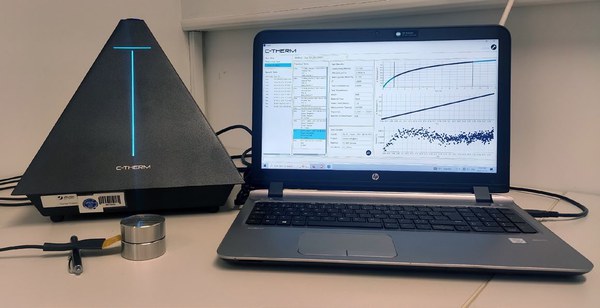

Thermal conductivity

The Trident “Thermal Conductivity Analyzer-Flex” uses the Transient Plane Source (TPS) technique, a double-sided hot plate sensor, to simultaneously determine the thermal conductivity, thermal diffusivity, and specific heat capacity of materials in a single measurement, in accordance with ISO standard 22007-2.

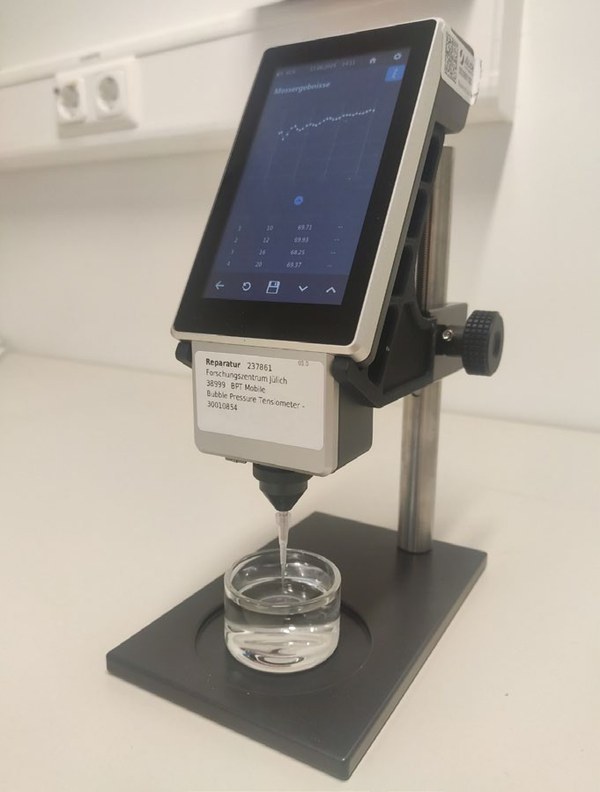

Bubble pressure tensiometer (BPT Mobile /Krüss)

The dynamic surface tension is determined using the “Laplace” pressure, whereby the maximum internal pressure of a gas bubble formed via a capillary in a liquid is measured.

Electrochemical analysis

The laboratory, which was set up specifically for the electrochemical characterization of battery cells, is equipped with four VMP-300 cycling systems (BioLogic) with a total of 32 channels for impedance measurements up to 7 MHz and a further 160 channels for pure cycling (BTS-5V100mA, Neware). A total of seven climate chambers with volumes ranging from 10 to 500 standard liters are available to ensure controlled environmental conditions during testing (Vötsch Industrietechnik GmbH and MaxiPower, Neware).

Ion beam analysis

The institute operates a beam line at the Jülich Tandetron accelerator, specifically for analysis in the battery sector. Here, all elements, including Li, can be quantified with high depth resolution (>100 nm) and lateral scanning (<20 µm). The specially developed AI-based evaluation of up to 10,000 measurement points per day enables 2D and 3D reconstruction of the element distribution in the components or full cells.

Optical emission spectrometry with inductively coupled plasma (ICP-OES)

This method allows quantitative multi-element determination in liquid samples and extracts or digestion solutions of solid samples. Digestion can be carried out with acids or by melting, with the analyte concentration and matrix concentration adjusted to the working range of the ICP-OES:

Maximum analyte concentration depending on the element in the range of approx. 5 mg/L to 100 mg/L. Maximum salt content in the sample (depending on the salt approx. 0.5 g/L - 1 g/L), maximum content of organic solvents (depending on the solvent approx. 5 -10%, possibly higher with other sample inlet systems). Acidification of samples to minimize losses in the sample inlet system; exception in case of sample instability when acid is added.

The sample solution is atomized and introduced as an aerosol into an argon plasma. In the plasma, the sample components are atomized and ionized. This produces characteristic emission radiation, which is spectrally analyzed via an optical system. The intensities of the emission lines of the elements to be determined are detected and evaluated. Calibration is performed with external standards, if necessary also via standard addition.

The iCAP PRO XP ICP-OES spectrometer (Thermo Fisher Scientific Inc.) offers highly sensitive and reliable multi-element analysis.

Simultaneous ICP-OES spectrometer from the iCAP PRO series (Thermo Fisher Scientific Inc.), which covers the entire wavelength range in a single measurement, with vertical plasma torch alignment for ultimate robustness (manufacturer's image).

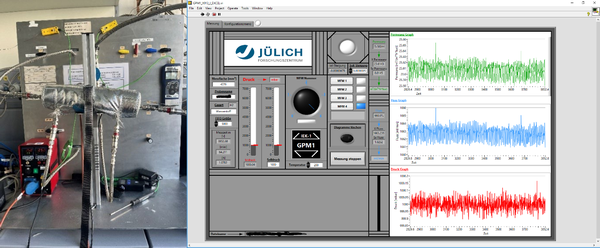

Single gas permeation test bench

Measurement of flow and permeance on microporous ceramic membranes with single gas to investigate the separation behavior of membranes. Gases used:

Measuring range:

o 100 - 5.000 mbar feed

o 0,015 – 2600 ml/min permeate

o Room temperature – 270°C

o Membrane tubes (250 mm x 10 mm), (105 mm x 10 mm), (47 mm x 10 mm)

o Membrane discs 39 mm x 2,2 mm

o Other geometries possible with suitable test cell

Permporosimetry

This method can be used to characterize porous ceramic membranes in terms of their pore size distribution and freedom from defects. It is a non-destructive measurement method and can be used for the evaluation and quality control of a membrane during the development phases.

Measuring principle:

o Capillary condensation in the mesopores

o The pore diameter increases with increasing relative humidity

o The permeance decreases with increasing relative humidity and an inert gas

- Inert gases used:

o Helium

o Nitrogen

- Measuring range:

o 1 ln/min

o 0 - 2.000 mbar

o Membrane tubes (250 mm x 10 mm), (105 mm x 10 mm), (47 mm x 10 mm)

o Membrane discs 39 mm x 2.2 mm

Test bench for characterizing fuel cells and electrolysis cells

The single-cell measuring station (manufacturer: EBZ) offers the possibility of characterizing solid oxide cells in fuel cell and electrolysis operation. Cells with a size of 5x5 cm² are used, which are tested in a ceramic housing. H2/H2O mixtures are available as fuel gases.

Spezifikationen:

Temperature range: 600–900 °C

Current: maximum 24 A

Humidification: evaporator in fuel gas and air flow

Contact: Au on air side, Ni on fuel gas side

High-temperature impedance measurement station (Novocontrol)

In the temperature range from approx. 150 °C to 1200 °C, the impedance of a sample can be determined using 2- and 4-point measurement methods. The frequency generator covers frequencies up to 1 MHz, and impedances from a few mΩto MΩ can be analyzed. Air and forming gas (2.9% H2 in Ar) are available as measuring environments and can be humidified in a bubbler. The samples are contacted via Pt nets.

Specifications:

Temperature: bis 1200 °C

Frequency: < 1 MHz

Impedances: mΩ to MΩ

Sample geometry: round, with a diameter of 20 mm or smaller

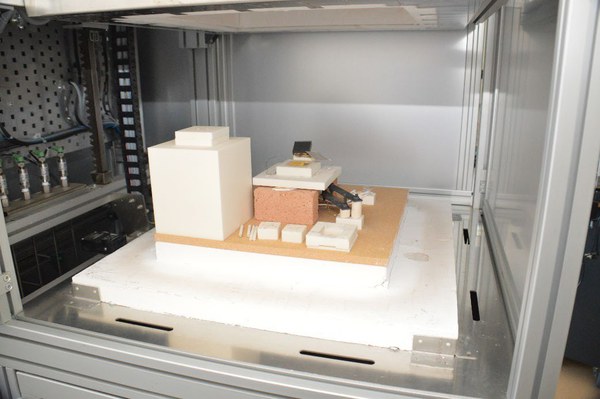

Thermo-optical measuring system Tommi Plus (Fraunhofer ISC)

Knowledge of sintering properties is essential for the manufacture of ceramic components. The Tommi Plus measuring system is used for contactless measurement of sintering shrinkage or curvature of test specimens in a variety of geometries. The influence of external forces (e.g., rods in conventional dilatometers) is avoided. At the heart of the setup is a furnace with two quartz glass viewing windows on two opposite sides. A lamp and a camera are placed in front of each viewing window, making it possible to take images of the sample silhouette during the temperature treatment.

Specifications:

· Temperature up to 1600 °C

· Sample diameter max. 50 mm

· High variability of sample geometry

· In-situ evaluation or subsequent evaluation based on the images

· Debinding and sintering possible in one furnace run

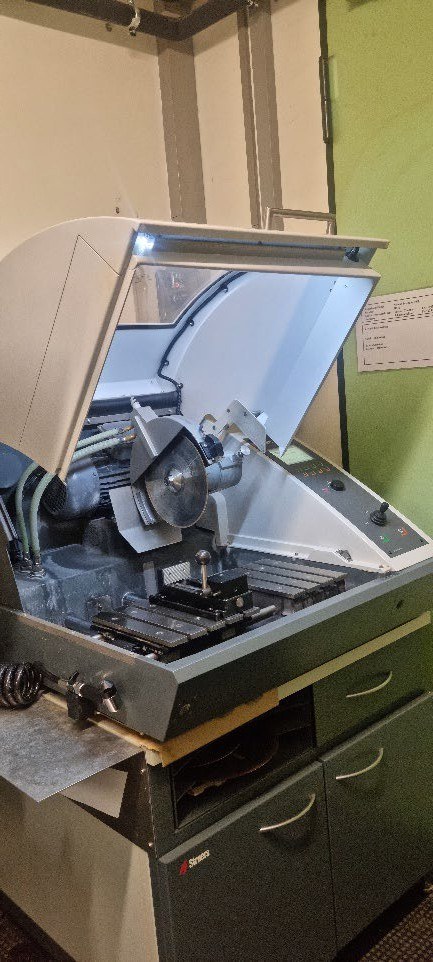

Materialography

Compressed air blasting equipment

In compressed air blasting, a powdered blasting material (e.g., sand, corundum, glass beads) is accelerated in an air jet onto a surface to be blasted and abrasively removes material from the surface. It is used either to clean surfaces of unwanted components or to condition/structure (e.g., increase the roughness) surfaces.