Instrument Technology

The Instrument Technology department develops new solutions for the automation of neutron scattering instruments and supports the instrument teams during construction and operation. It focuses the areas of automation and motion control. We develop a portfolio for driving and controlling a wide range of components to provide tailored solutions for individual instruments in close collaboration with the mechanical engineers and the instrument scientists. Here we cover the entire construction process from the concept, realization, testing and commissioning of instruments.

In addition, we assess novel technologies in the field on their potential for neutron scattering instruments.

Recently we have started to build up expertise in neutron scattering instrument simulation to support scientists during the design and optimization of new instruments.

Management: Jörg Voigt

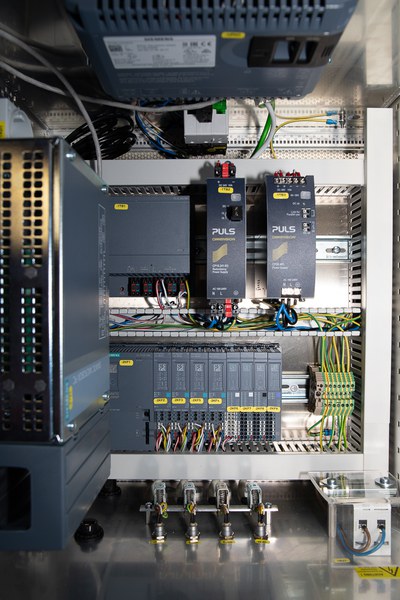

Automation and motion control

Modern neutron scattering instruments feature a large number of parameters to control, which provide optimized configurations for a variety of experimental challenges.

We develop the motion control technology for any component requested.

The installed systems guarantee at the same time the safe operation for humans and apparatus.

Contact: Harald Kleines, Frank Suxdorf

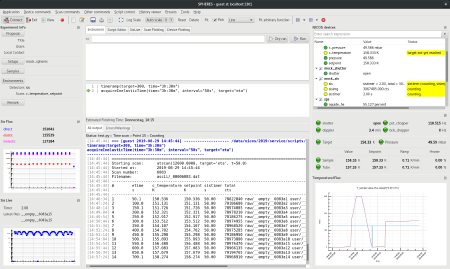

Control systems

For an easy and transparent access to individual instruments components, the partners at MLZ develop the Network Integrated Control System (NICOS). It is also used for the user control of x-ray equipment at the Jülich site. We use TANGO Controls for the object oriented device abstraction, complemented by TACO, EPICS or WinCC solutions if requested.

Contact: Alexander Steffens, Fabian Beule

Robotics and Neutron Scattering

More powerful neutron sources and more efficient instrumentation requires a higher degree of automation not only for the instruments, but also for the individual experiment. Recently, robots are introduced e.g. to perform re-occurring tasks like sample change 24/7 to improve the duty cycle of the instruments. We develop solutions for the safe operation in complex and adapting environments to explore the full potential of robotics for neutron scattering.

Contact: Sven Janaschke

Detektoren und Datenerfassung

Die zentrale Komponente eines Streuinstruments ist der Neutronendetektor. Wir unterstützen den Bau und den Betrieb von Detektoren und entwickeln bei Bedarf maßgeschneiderte Elektroniklösungen für die schnelle Datenerfassung. Daneben arbeiten wir mit internationalen Partnern an neuen Detektorkonzepten für die nächste Instrumentgeneration.

Contact: Ralf Engels, Günter Kemmerling

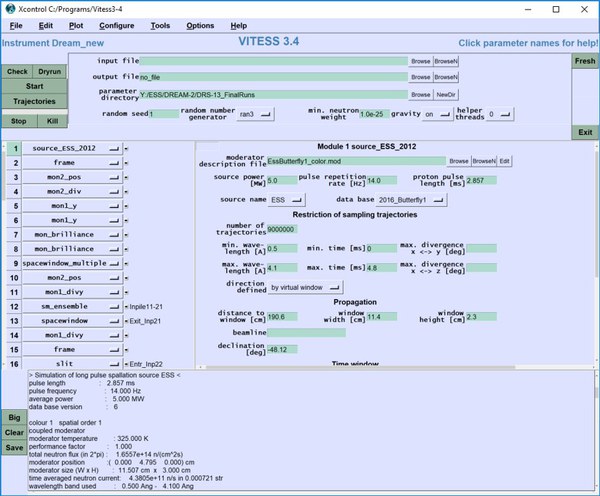

Instrument Simulation

Instrument simulation plays a crucial role today to optimize novel instrument concepts. Increasing computing power leads to more realistic models of the instruments, which may be even used to investigate resolution effects in the data analysis. The development of the Monte Carlo Software package VITESS is now continued in the department.

To address radiation protection issues of instruments and also novel neutron sources transport codes such as MCNP, FLUKA or GEANT4 are employed. The department provides the expertise to support the instrument teams with tools for the layout of shielding to meet the requirements not only of radiation protection, but also for very low background conditions to enhance the sensitivity of the instrumentation.

Contact: Klaus Lieutenant, Jörg Voigt

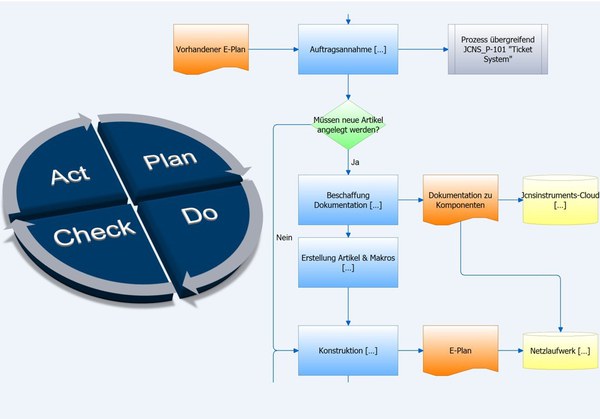

Quality management

We apply the methods of quality management not only to improve our instruments and devices, but also to continually improve the development process.

Our main activities include establishing and maintaing a quality management system for instrument technology, the coordination of the process for obtaining CE conformity in instrument and device manufacturing, and supporting the ESS project in the area of quality.

We also provide quality methods for the Institute and other associated projects.

Contact: Stephan Kleefisch