Microfluidics

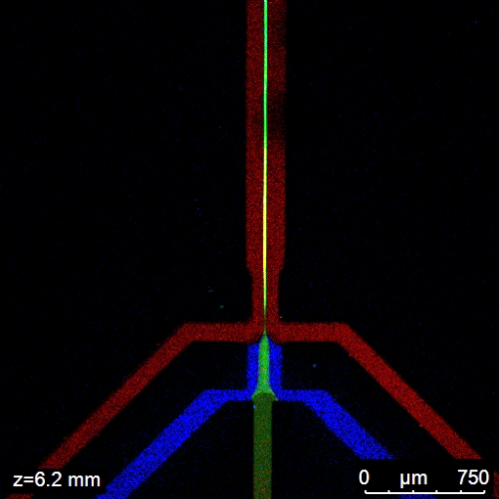

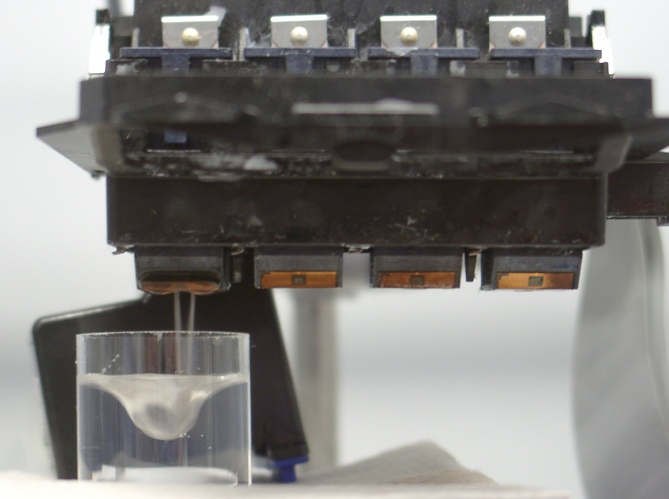

Microfluidic chips feature channels of 5 – 500 micrometer in diameter wherein liquids can be handled by means of various devices such as mixing crosses, turbulent mixers, reaction chambers, deceleration meanders in order to mix the fluids, start and follow reactions or investigate reaction pathways. The fluids are pumped through the channels using highly precise syringe pumps as well as pressure controlled pumping devices with flows in the microliter to milliliter per hour range. Microfluidics can be employed to fabricate colloidal structures such as (multiple) emulsions, hollow structures (vesicles), capsules, microgels, solid particles via precipitation or aerosols via a spray nozzle. Flow properties and flow profiles as well as mixing times and reaction kinetics can be investigated using fluorecent dyes or particles in combination with confocal and fluorecence microcopy technologies and particle image velocimetry. Due to similar channel / nozzle diameter, inkjet technologies also feature some of the capabilities of microfluidics.

At JCNS-1, microfluidic channel systems are in-house designed using 3D-construction software and fabricated via photo lithography as well as direct laser writing (HNF) followed by soft lithography. Larger channel system can also be directly fabricated using 3D printing technologies. The microfluidic channel systems are currently used to fabricate hydrogels for cell encapsulation, narrow distributed emulsions, tracing reactions via SAXS, confocal and optical microscopy or recording of reaction kinetics via fluorescence microscopy. A further application is the development of microfluidic rheometer.

Findings from the experiments can act as input parameters for FE-simulations using COMSOL software which helps to optimize the channel designs for the next step of development.

At JCNS-1, inkjet technologies are used for the production of colloidal systems and the spraying of thin layers of fluids onto substrates such as glass or silicon wafers.

References:

- X. Chen, J. H. Schröder, S. Hauschild, S. Rosenfeldt, M. Dulle, S. Förster,

Simultaneous SAXS/WAXS/UV−Vis Study of the Nucleation and Growth of Nanoparticles: A Test of Classical Nucleation Theory

Langmuir 2015, 31, 11678-91 - U. E. A. Fittschen, N. H. Bings, S. Hauschild, S. Förster, A. F. Kiera, E. Karavani, A. Frömsdorf and J. Thiele,

Characteristics of Picoliter Droplet Dried Residuesas Standards for Direct Analysis Techniques

Analytical Chemistry 2008, 80(6), 1967-77S. - Hauschild, U. Lipprandt, A. Rumplecker, U. Borchert, A. Rank, R. Schubert and S. Förster,

Direct Preparation and Loading of Lipid and Polymer Vesicles Using Inkjets

Small 2005, 1(12), 1177-80.

Contact:

Dr. Stephan Hauschild

Staff Scientist

- Jülich Centre for Neutron Science (JCNS)

- Neutron Scattering and Soft Matter (JCNS-1)

Room 281