Plastics upcycling

Emerging evolution

Upon the development of traditional plastics their high stability was a very desirable feature, little though was given to their end-of-life fate. Now, half a century later, plastic pollution is everywhere. Even worse, plastic is not a pure homogenous recalcitrant substance but a complex mixtures of polymers, plasticizers, protectives, pigment, coating materials etc. Amazingly, nature is already starting to adapt even after this very short evolutionary timespan. We are finding microbes that can degrade recalcitrant plastics like PET, PA, PU or coating materials. These microbes have enzymes that can break down the polymer to its monomeric constituent, and sometime they even have the metabolic pathways to then consume these plastic monomers.

Engineering plastic-degrading enzymes

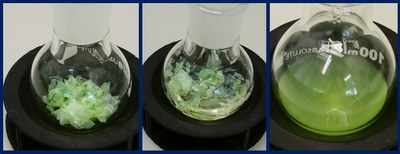

We are discovering plastic-polymers and -coatings degrading enzymes in diverse natural habitats such as our oceans, but also in places with very high microbial activity like composting facilities. Given the incredibly short time these enzymes had to evolve on plastics, they will usually only have a minor, moonlighting activity on man-made polymers. We accelerate this evolution in the laboratory, creating specialized variants with greatly increased plastic-degrading activity. These enhanced enzymes enable the depolymerization of plastic waste. We develop secretory production with established biotechnological platform strains like Corynebacterium glutamicum and novel isolates. The resulting monomers can be purified and recycled into new polymers, or they can be fed to microbes in fermentation processes.

Microbial conversion of plastic monomers

Unlike typical biotechnology substrates such as sugars, many plastic monomers are not common in nature. As a result, their biodegradation is often limited to a few organisms in specific environmental niches. We, therefore, engineer microbial biotechnology workhorses such as Pseudomonas putida and Geobacillus to metabolize plastic monomers. This engineering then allows for the conversion of complex plastic hydrolysates into value-added chemicals and biopolymers, leveraging the decades of experience we have with bio-based microbial catalysis to enable plastic-based microbial conversions and circular life cycles for sustainable polymer solutions.

Current

projects

UPLIFT sUstainable PLastIcs for the Food and drink packaging industry

Glaukos Circular solution for the textile industry

MIX-UP MIXed plastics biodegradation and UPcycling using microbial communities

LipoBiocat Robust and selective biocatalysts für industrial applications

FutureEnzyme Technologies of the Future for Low-Cost Enzymes for Environment-Friendly Products

AI MareExplore Utilizing AI for marine enzyme discovery to address human-made grand challenges

SPHERE - Syncom Synthesis of Plastics: Helmholtz Expertise in Plastic Research and Policy Engagement" – addresses the global challenge of plastic pollution by consolidating and advancing knowledge on the end-of-life management of plastics.