Extremely strong: High-performance fibers at the maximum theoretical limit

A new spinning process opens the way to synthetic high-performance fibers with high strength and high toughness

Jülich, 13. December 2019 – Scientists from Germany, China and Switzerland have achieved a breakthrough in the fabrication of synthetic high-performance fibers. The researchers from the University of Bayreuth, the University of Halle, RWTH Aachen University, Jiangxi Normal University, ETH Zurich and the Forschungszentrum Jülich succeeded to fabricate synthetic high-performance fibers with higher strength and toughness than hitherto existing fibers.

The fabrication employs a concerted spinning and treatment process, where microfiber yarns are drawn and chemically crosslinked in the state of highest orientation. The fabrication process could be demonstrated for polyacrylonitrile fibers and can be applied to a broad range of fiber materials. The results published in the current issue of Science opens new possibilities for future applications of synthetic high-performance fibers in the area of energy materials, e.g. wind energy, of lightweight materials, in aerospace as well as high-tech sport and outdoor applications.

High-performance fibers have outstanding mechanical properties. They are high-performance materials that can be fabricated from metals, ceramics, carbon and polymers. Polymer high-performance fibers combine excellent mechanical properties with low weight. For example, Kevlar fibers have a 6-8-times higher tensile strength compared to steel fibers, at only one fifth of their weight. Polymer high-performance fibers are key components in high-strength materials with applications in the energy sector and in lightweight construction, two large and important future technology areas.

The two key properties of high-performance fibers are high tensile strength and high toughness. High tensile strength can for some polymer materials be achieved using high drawing ratios (e.g. for UHMW-PE/Dyneema) and high molecular orientation (e.g. for Aramid/Kevlar) during the fiber fabrication process. The fabrication of polymer fibers with high tensile strength and high toughness is a great challenge. Low toughness leads to wear, decreases lifetime and represents a weakness in the material properties, which prevents their use in a broad field of applications. So far only spider silk as a material optimized by nature fulfills both requirements for high strength and toughness.

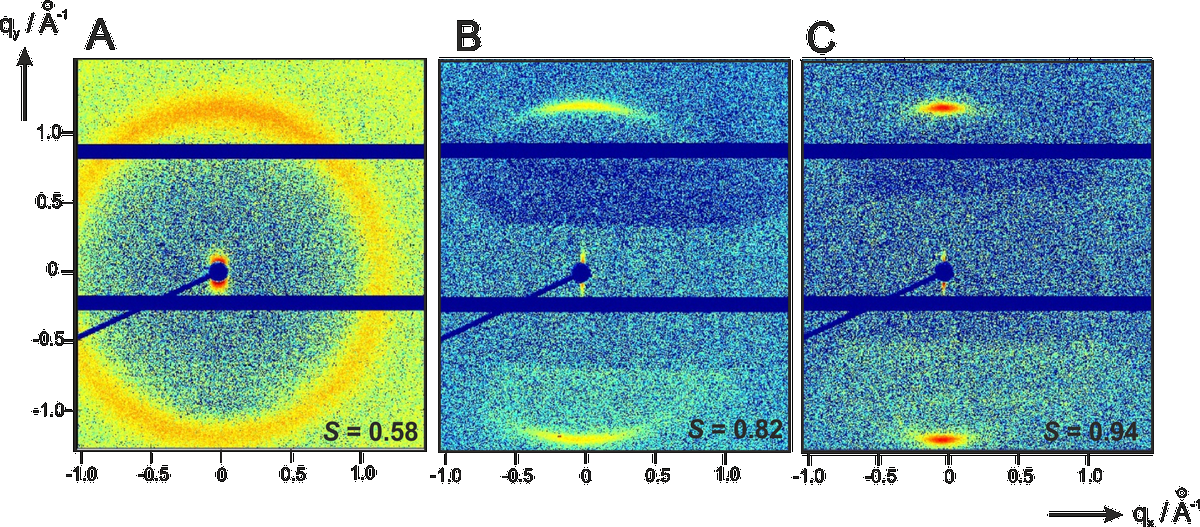

In principle, high strength and high toughness could be achieved, when primary fibers can be spun into a parallel aligned, highly oriented fiber bundle or yarn, and then stably connected in the state of highest orientation. The high degree of orientation leads to high tensile strength, and the stable connections lead to high toughness. The researchers could achieve this for the first time establishing a new spinning and thermal annealing process. Using electro-spinning they could fabricate very uniformly aligned, crystalline yarns, which in a subsequent concerted process at higher temperatures where drawn to highest orientation and covalently crosslinked in the drawn state. This process could be demonstrated for polyacrylonitrile copolymers (PAN), which contained a small amount of cross-linkable methacrylate units. Covalent cross-linking was achieved with a bifunctional polyethylene glycol bisazid via a [2+3] cycloaddition. Using this process it was possible to fabricate PAN-yarns with a tensile strength of 1240 MPa, a tensile modulus of 13.5 GPa, and a fracture toughness of 137 J/g. The new fiber material therefore has tensile strengths in the range of the best high-performance fibers, a tensile modulus that is at the maximum of the theoretical limit, and a fracture toughness which is larger than for spider silk. 0.008 mg of such a fiber can lift a weight of 30g , 4-million-fold its own weight. The fabrication process was demonstrated for a commercial fiber material, PAN, and can be applied to a broad range of synthetic fiber materials. This opens new opportunities for a broad spectrum of future applications in the area of energy materials, for light-weight construction and automotive materials, for aerospace industry as well as for sports, outdoor and high-tech-textile applications.

Original publication:

X. Liao, M. Dulle, J. M. de Souza e Silva, R. B. Wehrspohn, S. Agarwal, S. Förster, H. Hou, P. Smith, A. Greiner, High strength in combination with high toughness in robust and sustainable polymeric materials

Science (13 Dec 2019), DOI: 10.1126/science.aay9033

Further Informations:

Jülich Centre for Neutron Science - Neutron Scattering and Soft Matter (JCNS-1/ICS-1)

Press Release of the University of Bayreuth

Contact:

Prof. Dr. Stephan Förster

Jülich Centre for Neutron Science (JCNS-1)

Tel.: +49 2461 61-85161

E-Mail: s.foerster@fz-juelich.de