Self-testing the energy turnaround: the Living Lab Energy Campus

The Jülich campus becomes a real laboratory for energy transition. The aim of the Living Lab Energy Campus (LLEC) project is to investigate the interactions between technology, energy sources and consumers in order to design practical and scalable solutions. The Federal Government, the Helmholtz Association and the state of North Rhine-Westphalia are supporting the LLEC with a total of € 22.7 million until the end of 2021.

Renewable energies, in particular wind and solar energy, are to be increasingly used in the context of energy transition. The familiar problem therein: this type of energy production fluctuates greatly, both over the day and over the year, but this also applies to energy consumption. An office building complex, which is mainly used during the day, has a different rate of energy consumption than a laboratory or a supercomputer that also runs at night.

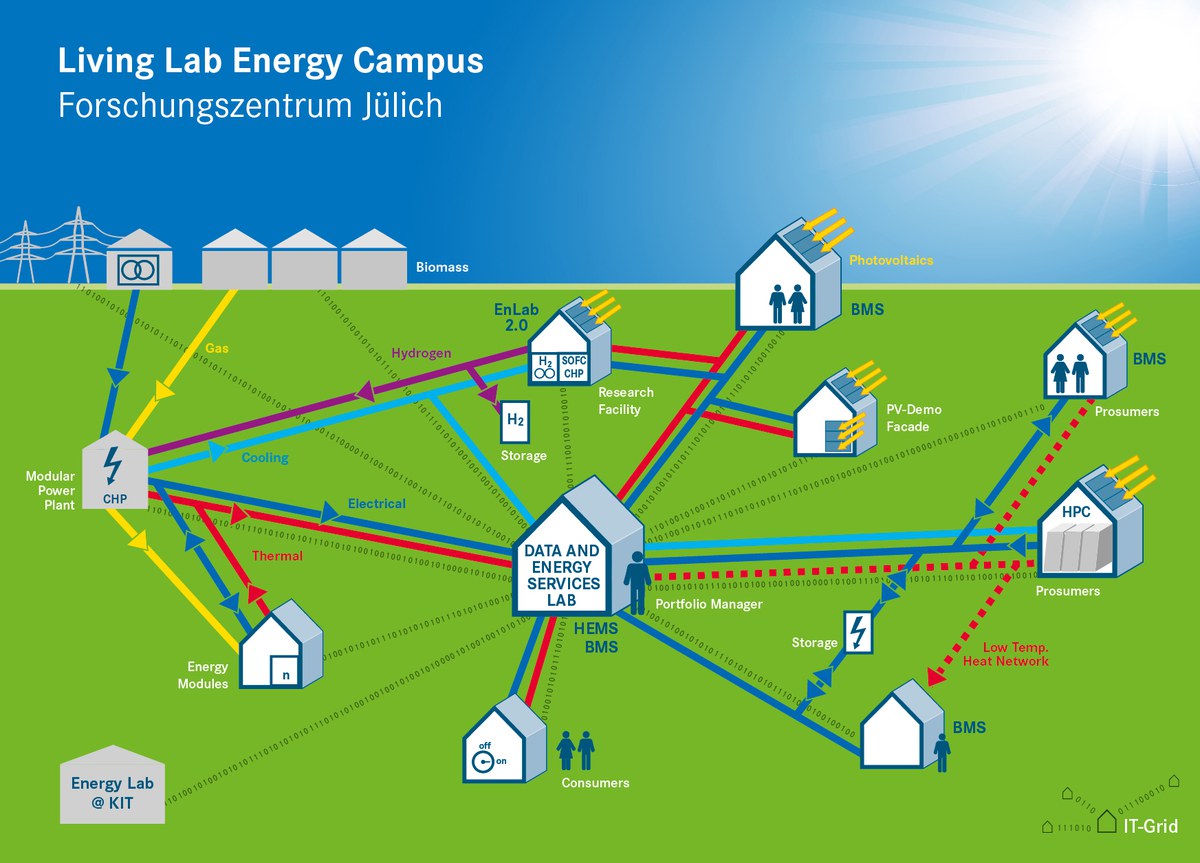

New conversion and storage technologies that include not only electricity but also heating and cooling are required to make energy available as needed. The technical term for this is integrated energy. “We are therefore not only looking at electricity, but also heat at different temperature levels and chemical energy in the form of hydrogen,” explains Dr. Stefan Kasselmann, head of the Living Lab Energy Campus (LLEC) project. This opens up new opportunities for the use of energy. However, it also makes the project more complex (see also project modules).

But where and when is what amount of energy produced and consumed? In order to, on the one hand, measure and, on the other hand, realistically forecast this, the Jülich experts rely on an appropriate sensor and data network as well as on intelligent control systems. These analyse a wide range of information from buildings and facilities, include yield forecasts and weather forecasts and can thus calculate strategies for an optimal energy supply.

Forschungszentrum Jülich is now testing on a part of its own campus whether and how this can work out within a manageable scope. To this end, it uses its institutes’ broad expertise in research and infrastructure. More than ten organisational units are working together on an interdisciplinary basis in the LLEC project, including many areas of the Institute of Energy and Climate Research, of Planning and Building Services, Building and Property Management, the Sustainable Campus administrative department and the Central Institute for Engineering, Electronics and Analytics.

Specifically, the project provides for a series of modules, all of which should optimally complement each other.

Modules of the Living Lab Energy Campus

The new full heating system replaces the previous district heating from the Weisweiler coal-fired power plant. Natural gas/biomethane or hydrogen can be used as energy sources. In the long term, hydrogen is to replace fossil fuels as far as possible.

Auf dem Campus werden verschiedene Photovoltaik-Systeme errichtet. Sie bilden die Grundlage der regenerativen Stromversorgung. Neben klassischen Dachinstallationen wird es auch freistehende Module geben. Außerdem wird erprobt, wie Solarzellen in Fassaden, Überdachungen oder Gehwege integriert werden können.

No matter what the weather: the fluctuating infeed of the photovoltaic systems is compensated for by two large lithium-ion batteries, which temporarily store the solar power. At the same time, these batteries support an uninterruptible power supply (UPS) for parts of the Jülich supercomputer.

A new hydrogen infrastructure with fuel cells and innovative storage technologies is being built. Forschungszentrum Jülich produces the hydrogen itself in the newly built electrolyser. The basis is “excess” solar power from the photovoltaic systems, i.e. solar power that is not used immediately. The hydrogen produced in this way can be used for heat and power generation or, for example, as fuel for hydrogen cars.

The “brain” of the LLEC system will be the Data and Energy Services Lab, a control centre based on an innovative IT platform that is being developed at Forschungszentrum Jülich. It combines innovative methods from data science, simulation, optimisation and forward-looking control concepts.

New control models

How exactly does it work? “The first step is to create a digital image of the campus,” explains Stefan Kasselmann. “Then we define virtual rooms – we speak of system boundaries within which energy generators, energy storage devices and consumers interact with each other and optimally coordinate the individual components.” The project team then looks, for example, at how large a photovoltaic system, a battery store or an electrolyser for hydrogen production must be designed in order that the entire network eventually achieves a specified proportion of renewable energies. “For the design of such a network as well as for optimal operation, we want to develop new control models that take into account the weather, energy usage behaviour and future infrastructure requirements of Forschungszentrum Jülich, for instance.” The scientists can then test the models in the real campus environment and continuously develop them further.

Voices from the project

“Power supply for the campus operations must be guaranteed while we integrate new modules into the energy supply.”

“We are permanently between conflicting priorities with this project because at LLEC, we work with many, partly still unknown influencing variables, but at the same time we have to maintain operation of the buildings and energy supply. Integrating the demonstrators could therefore be compared to open-heart surgery. For example, an IT-supported control system must be developed to ensure that we primarily use the regenerative energy generated in operation or else store it. There is also the question of how we want to allocate the energy, since we would like to influence prosumer behaviour with smart metering in the future. In any case, it is a great task for us to work closely with science on such a forward-looking project with our ideas and our knowledge of the infrastructure.”

Mark Franken, Member of the Executive Committee, Facility Management

“We push the limits of what is feasible to cut costs”

“Building an electrolyser is nothing new to us. However, the LLEC gives us the opportunity to test the interactions with other components of a renewable energy supply in practice – after all, the electrolyser serves to convert the self-produced solar power into hydrogen as an energy carrier. The hydrogen produced in this way can be stored and used as fuel for fuel cell vehicles, for power recovery or for heat supply. The question will be: do we assess the dynamics of the system correctly? And which components might need to be adapted? We also develop new ideas, for example to reduce costs. Because only if we can develop a low-cost electrolyser can the principle be successfully applied to comparable projects. We must therefore push the limits of what is feasible, especially when it comes to reducing the use of materials and increasing performance.”

Dr. Martin Müller, Team Manager Hydrogen

“Our simulation is implemented on campus”

“In order to integrate renewable energies into decentralised energy systems, different energy flows have to be coupled and considered holistically. To this end, we are developing a platform for information and communication technology (ICT) that combines innovative methods in areas such as data science, simulation, optimisation and predictive control concepts. Thanks to the digital image of the campus, the platform allows both the planning of future change measures and optimal operation of the energy infrastructure. The development of the software is an exciting task in which the scientific institutes and departments of the infrastructure work very closely together. What is great about the LLEC: many other projects often remain in the theoretical study stage. Here, however, things will be implemented in real terms on campus. And that makes the task more exciting.”

Dr. André Xhonneux, Team Manager Simulation

“Everybody contributes to the success of the LLEC”

“For the energy transition to succeed, the human factor must also be considered. The central question in the Engagement subproject is how we encourage individual employees to support the joint development of the LLEC through technical expertise and conscious behaviour. For example, colleagues receive information on the energy consumption of their building. At the same time, we want to provide targeted information about opportunities for participation and launch various activities to this end, including playful ones – such as activities in which employees can measure the effect of their behaviour themselves. To this end, we are developing standard knowledge transfer and participation processes further for this project. Thus, everybody will be able to become part of the transformation.”

Dr. Ellen Kammula, Team Manager Engagement

“We are tackling 30 individual projects – a logistical challenge”

“We have a lot to do. The work to be done from seven thematic areas is divided into about 30 individual construction projects for us. The logistical challenge is huge, as can be seen from the photovoltaics (PV) example. On the one hand, we plan PV systems in open areas and on new buildings, and on the other hand, PV modules are additionally installed on existing buildings, where we have to clarify questions such as roof load, lightning protection and permits. In addition, we sometimes integrate the installation into ongoing construction measures. Another example is the local heating in the area around the Jülich Supercomputing Centre, which will in future be provided via the waste heat from the supercomputer. This is technically very complex – and for us, it is new and particularly exciting how closely we work together with the scientists.”

Martin Schuldt, Team Manager Planning and Building Services