Heat Without A Flame

Pioneers – From Lab to Launch

Clean, affordable, and efficient heat generation. Simon Hahn is determined to make it possible.

May 2025

Catalytic Combustion Instead of Nitrogen Oxides

Many products require heat during manufacturing — such as steel, plastics, and paper. Typically, this means temperatures above 100 degrees Celsius. To generate this heat, natural gas and oil are usually burned using an open flame. However, this process releases harmful emissions such as nitrogen oxides (NOₓ) and CO₂. More than half of industrial greenhouse gas emissions come from such processes.

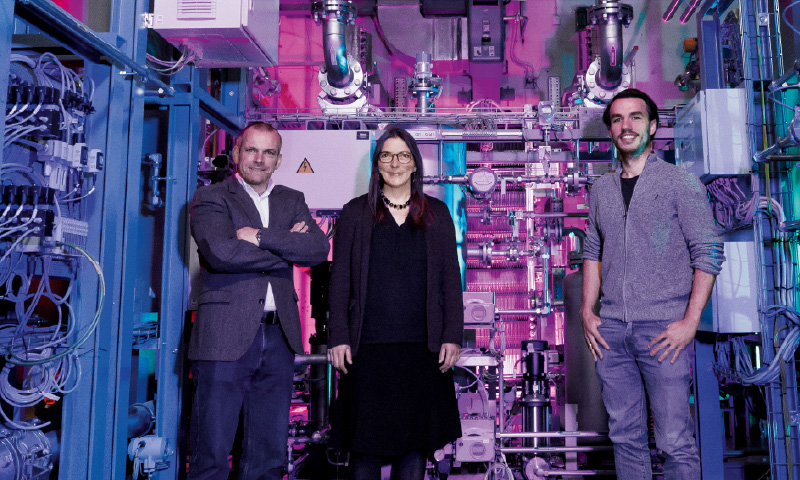

Simon Hahn Wants to Bring His Research to Market

Spin-off: Clean H2eat

The chemical engineer from Jülich is preparing his spin-off at the

Institute for a Sustainable Hydrogen Economy (INW).

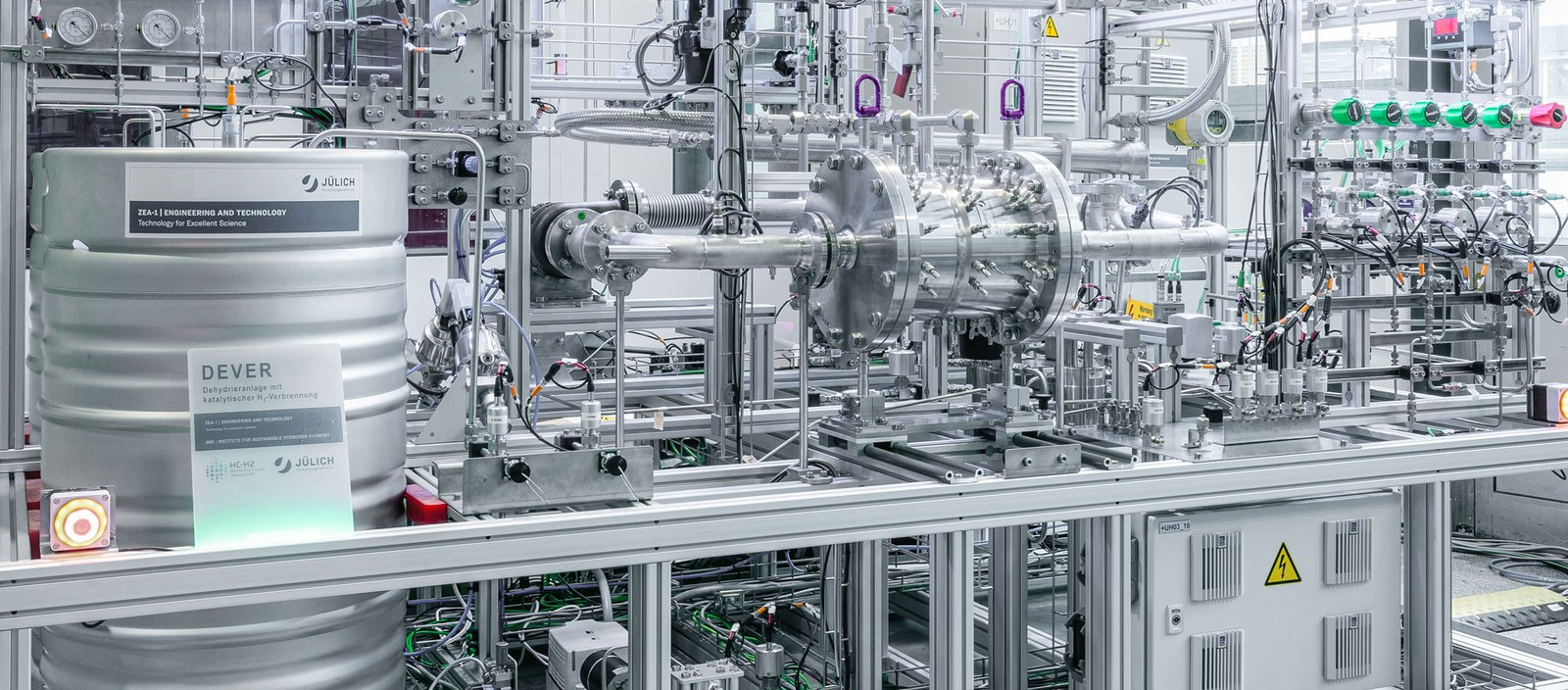

Jülich-based chemical engineer Simon Hahn wants to prove that there’s a better way. His solution: catalytic combustion of hydrogen. In this method, the fuel is oxidized using catalysts and added air — without an open flame and at temperatures below 500 degrees Celsius. When hydrogen is used, the result is steam and heat — with no harmful emissions whatsoever. At Forschungszentrum Jülich, Hahn developed a technology based on this approach that delivers heat with exceptionally high efficiency, helping to significantly reduce fuel costs.

Pilot Partner

Through ongoing exchange with researchers and industry partners, Simon Hahn recognized the true potential of his innovation. This led to the founding project Clean H2eat. With support from the Jülich Innovation & Entrepreneurship Certificate Program (JUICE), the research center helped him develop a viable business model. Now, with backing from the Venture Architect Program at the Start-up Village in Brainergy Park Jülich, he is working to turn that model into a full-fledged business plan.

The JUICE Program: Learning Innovation and Entrepreneurship at Forschungszentrum Jülich

Hahn describes his technology as emission-free, compact, efficient, and flexibly controllable. “It can deliver heat wherever it’s needed — from industrial plants to private homes,” he emphasizes. Together with the Jülich Institute of Technology and Engineering (ITE), he has built a first demonstration-scale system: the DeVer demonstrator. The next step, as part of the spin-off, is to develop a full-scale industrial prototype. To make that happen, Hahn is currently raising funding. “Industry needs affordable, future-proof solutions — and that’s exactly what we aim to deliver,” says Hahn.

A Problem Solver in the Park: Simon Hahn and His Business Idea

Image credit: Guido Jansen; Bernd Nöring / Forschungszentrum Jülich

Looking Deeper: The Current Issue

When research, industry, and society unite their perspectives, they create solutions greater than the sum of their parts.

In the Endeavours magazine, discover how co-creation works — through real stories of collaboration, pioneering spirit, and successful transfer.