Nothing but Hot Air?

Co-Creation – Project DERIEL

As early as 1766, Henry Cavendish identified hydrogen as a distinct element. He called it “flammable air” – a nod to its high energy density. Antoine Lavoisier later gave it the name hydrogène – “water-forming.” A fitting choice, since when hydrogen is burned, the only byproduct is pure water.

June 2025

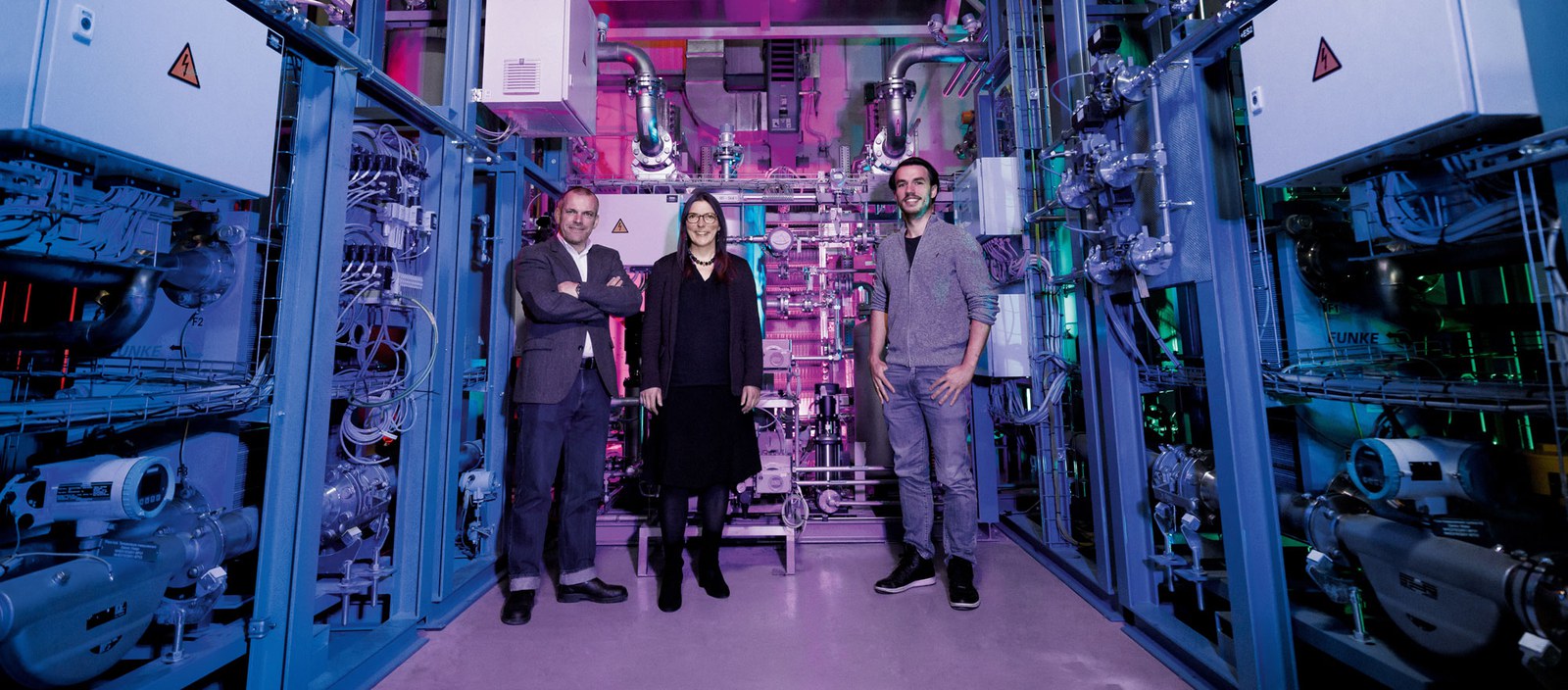

In front of the DERIEL test facility: Arne Schlegel, Dr. Eva Jodat, and Dr. André Karl (from left) at the impressive electrolysis test station at IET-1.

Key component of the energy transition

More than 250 years later, the lightest and most abundant element in the universe is once again in the spotlight – as a key building block for the energy transition, provided it is produced cleanly. Hydrogen gas can be generated in pure form through various methods. The most climate-friendly option is green hydrogen, produced by using electricity from renewable sources to split water into oxygen and hydrogen – entirely without fossil fuels. The devices needed for this process are called electrolyzers.

"If we manage to produce hydrogen on a large scale using these systems and integrate them into everyday life, we can revolutionize industrial production, free transportation from fossil fuels, and offer households a clean source of energy," says Prof. Rüdiger-A. Eichel, Director at the Institute of Energy and Climate Research (IET-1). Hydrogen technologies therefore hold enormous economic potential.

Many countries are researching efficient, reliable electrolyzers. In Germany, for instance, this is happening through the DERIEL project. Coordinated by Siemens Energy, the project brings together several companies with scientific partners such as the Max Planck Society, RWTH Aachen University, and Forschungszentrum Jülich. Rüdiger-A. Eichel is one of the leading figures in the project. DERIEL is part of the German government's flagship hydrogen program H2Giga, funded by the Federal Ministry of Education and Research, which aims to scale up the industrial production of electrolyzers and secure the supply of green hydrogen in Germany.

»If we manage to produce hydrogen on a large scale and integrate it into daily life, we can revolutionize industrial production.«

Prof. Rüdiger-A. Eichel

Cost and Durability

DERIEL takes things a step further: in addition to focusing on efficiency and reliability, the project aims to reduce costs and extend the lifetime of electrolyzers – key conditions for economic viability and a greener future.

At the heart of this effort is a new test facility at IET-1 in Jülich. Covering around 50 square meters, it can accommodate full-scale industrial electrolyzers and is equipped with state-of-the-art sensors. "Our test facility is unique in its size," explains Dr. Eva Jodat, who leads the project along with Dr. André Karl.

PEM electrolysis: a hope of the energy transition

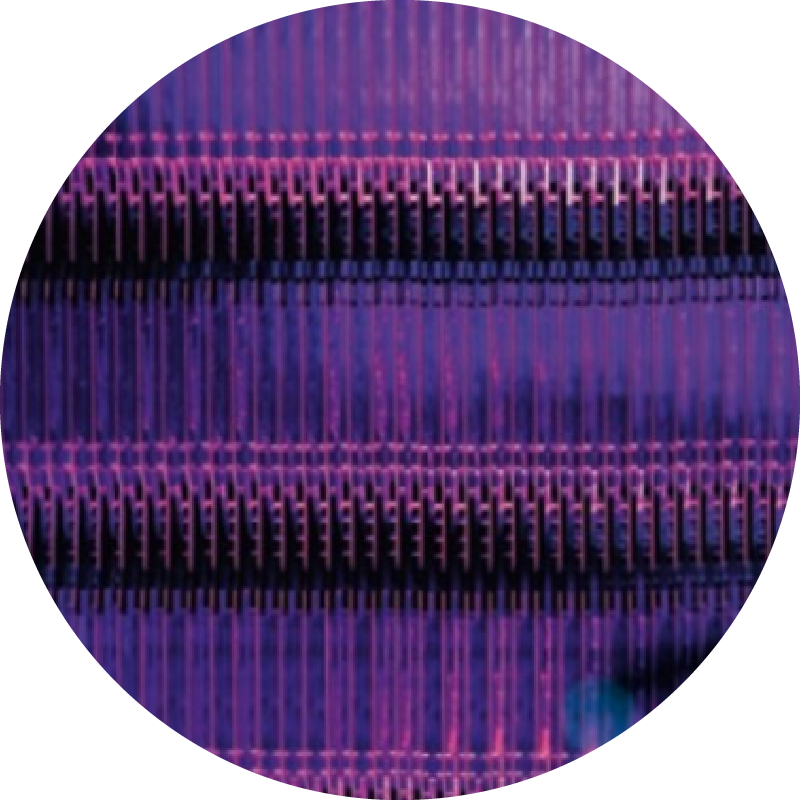

The facility focuses on so-called PEM electrolyzers, which are more susceptible to wear due to their higher capacities. However, this type of electrolyzer is particularly well-suited to operation with renewable energy, which fluctuates with the weather. They use a polymer membrane to split water into hydrogen and oxygen. This membrane is known as a Proton Exchange Membrane, or PEM. "Using high-tech microscopy, we examine material samples for stress points – and then identify more suitable materials," says Karl.

The heart of the system

where electricity splits water – and hydrogen is born.

A Shared Mission

The test facility is more than just a site for research – it’s a living example of co-creation in action. Here, the project plays to one of its greatest strengths: through close collaboration and knowledge-sharing between science and industry, the technology is optimized and built into a stable foundation for the future hydrogen economy.

"Only if we all pull together can we take the necessary steps toward a sustainable and independent future," says Eichel. With the new DERIEL test facility, project partners are pushing the technology forward and ensuring that new insights feed directly into industrial applications.

»Our test facility is unique in its size.«

Dr. Eva Jodat

Co-leads the DERIEL project with Dr. André Karl

The Key to Climate Neutrality

DERIEL is a flagship project for research-industry collaboration – with solutions designed not just to work in theory, but in practice. Because the path to the energy transition is both a technological and collaborative process – from research and industry to policy.

If we succeed in producing hydrogen at scale and integrating it into everyday life, we will have laid the groundwork for an independent energy supply for future generations. A giant leap for the energy transition – powered by nothing but water and, well… flammable air.

Two Enablers for Green Hydrogen Come from Jülich

Source: Bernd Nörig / Forschungszentrum Jülich

Dive deeper into the current issue

When research, industry, and society unite their perspectives, they create solutions greater than the sum of their parts.

In the Endeavours magazine, discover how co-creation works — through real stories of collaboration, pioneering spirit, and successful transfer.