Agrivoltaics combines agriculture with the generation of solar power on the same area of land. Photovoltaic (PV) modules are installed above arable land, allowing food crops or renewable raw materials to be grown at the same time. This smart dual use reduces competition for land and makes an important contribution to climate protection, the energy transition, and the preservation of biodiversity.

Jülich scientists from the Institute of Bio- and Geosciences (IBG-2) are collaborating with the Institute of Energy Materials and Devices (IMD-3) and the Living Lab Energy Campus (LLEC) to research various agrivoltaic systems both on campus and outside Forschungszentrum Jülich. The aim is to better understand the influence of different types of solar modules on plant growth and thus help drive practical developments.

Agrivoltaics research in and around Forschungszentrum Jülich

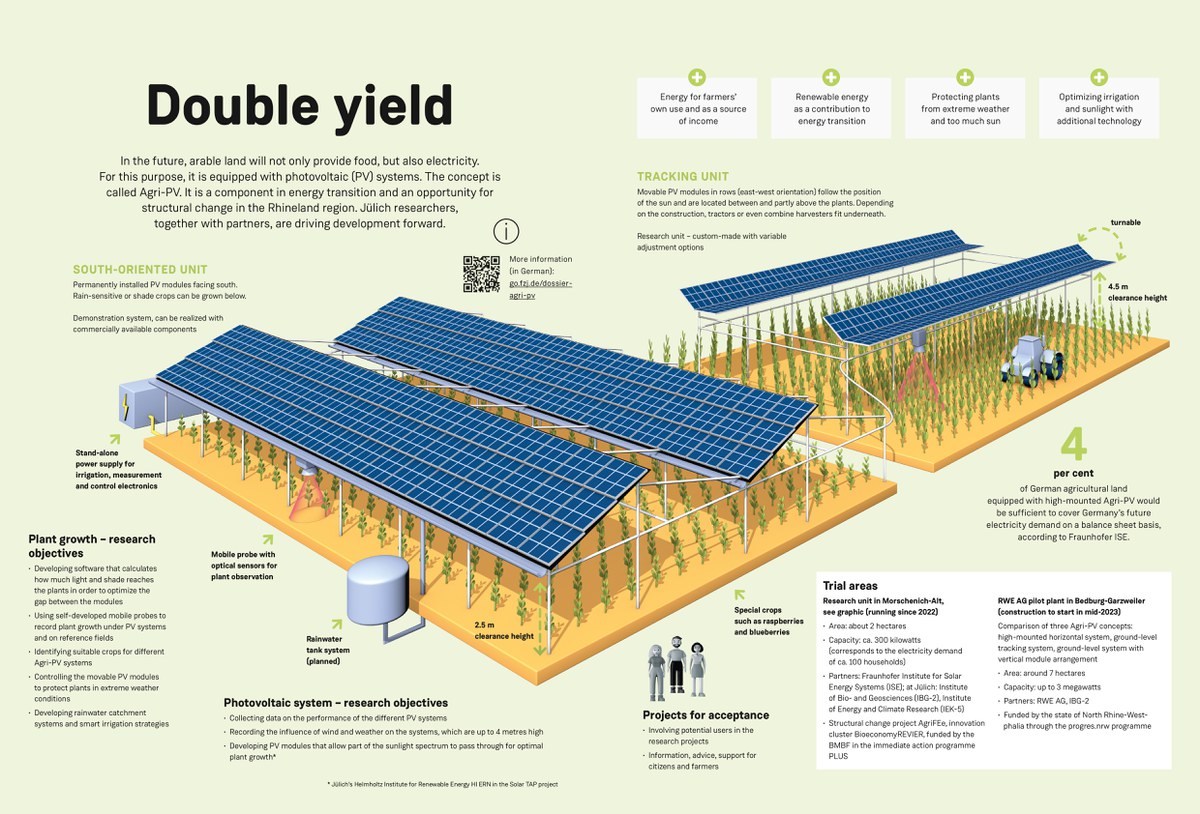

Forschungszentrum Jülich currently operates several research and demonstration facilities in the Rhenish mining area in cooperation with various partners. Three different types of agrivoltaic concepts are being used:

- Solar modules are mounted vertically on the support structure, leaving sufficient space between the rows of modules for harvesting equipment.

- Solar tracking systems move the PV modules so that they always face the sun. These modules can be arranged in rows or mounted horizontally above the crops.

- With elevated systems, PV modules are mounted on a pergola-like structure. The systems are installed in such a way that tractors or even combine harvesters can drive beneath them. Shade-tolerant plants or plants that are sensitive to rain are suitable for cultivation under these solar systems.

Practical projects that serve as a model

The researchers started work in 2019 with the BioökonomieREVIER structural change initiative. In Bürgewald (a municipality of Merzenich), the first agrivoltaic system was built in what is now the Agri-Food-Energy Park. Field trials are being conducted there using two different solar canopy systems. Close collaboration with agriculture, politics, and civil society provides crucial impetus for practical developments. The experience and results obtained from the agrivoltaics research have led to further projects in the Rhenish mining area.

Examples of agrivoltaics research in Jülich

Advantages and challenges of agrivoltaics

Agrivoltaics not only promotes plant growth, but can also enhance biodiversity on agricultural land – for example, through wildflower strips or nesting sites on the module structures. At the same time, it opens up new sources of income for farmers through the marketing of solar power, for example as operators, lessors, or direct sellers.

But it also involves higher investment costs: agrivoltaics sometimes requires special transparent modules or more complex structures with larger spacing. These additional costs have to be offset by agricultural yields to make them economically viable. However, some studies have shown that land use efficiency with agrivoltaics can exceed 100 %, meaning that the use of agrivoltaic systems can generate a greater total yield from biomass and electricity than a field or a solar installation alone.

Jülich research results incorporated into new regulations

The development of agrivoltaics in Germany is increasingly supported by clear regulations. In May 2021, the first DIN SPEC on agrivoltaic technology was published, outlining the technical and agricultural requirements for agrivoltaic systems. It defines minimum requirements such as a clearance height of 2.1 m for the cultivation of fruit and the need to maintain a yield of at least 66 % compared to areas that do not involve the use of PV.

This pre-standard is now being incorporated into key regulations: the Renewable Energy Sources Act (EEG) links special subsidies to compliance with these standards, and the German federal building code (section 35) permits agrivoltaic systems of up to 2.5 ha in outdoor areas without a development plan. Jülich actively contributes its research results to expert committees, for example through its involvement in the association for sustainable agrivoltaics (VnAP) or in commissioned research for the German Federal Ministry for Economic Affairs and Energy. FZJ is thus helping to develop the technology in a practice-oriented way and make it marketable.

Participating institutes

Jülich experts on agrivoltaics

Dr. Matthias Meier-Grüll, head of the Agri-Food-Energy Park (AgriFEe) innovation laboratory

“Agrivoltaic systems not only produce green electricity, they also protect plants from the sun, heat, and dehydration, as well as extreme weather conditions such as hail or heavy rain,” says Dr. Matthias Meier-Grüll from IBG-2, head of the BioökonomieREVIER Agri-Food-Energy Park (AgriFEe) innovation laboratory. “That’s why such systems have mostly been used in parts of the world where there is a lot of sun and aridity – for example, in the fruit-growing areas of southern Italy or France,” says Meier-Grüll. “With summers getting hotter and extreme weather events on the rise, agrivoltaic systems are also becoming increasingly important for our region. “We want to use field trials to find out which types of PV systems make sense for which crops – and how land can be used as efficiently as possible to ensure that dual use really is worthwhile,” says Meier-Grüll. “We also talk to farmers and researchers from all over the world who are already using agrivoltaics.”

The structural change project is primarily about our own region: “We learn a lot through critical discussions with farmers from the Rhenish mining area and beyond, while also supporting them with our research knowledge,” says energy researcher Meier-Grüll. “However, many are still sceptical about whether they can start using the new methods – for example, because of the high investment costs involved. For crops such as cereals and potatoes, systems require substantial spacing for large agricultural machinery.” However, “PV canopies” are suitable for special crops such as berries, herbs, or lettuce, which are sown and harvested differently and achieve higher yields for farmers. “Many farms in the region are already interested. We are helping them to break new ground in a well-informed, fact-based manner.” Ultimately, it is not about huge fields full of PV structures, stresses Meier-Grüll. “Using just two percent of arable land, agrivoltaics could already make a huge contribution to the energy transition in Germany.”

Prof. Ulrich Schurr, institute director, on FZJ’s supporting role

There is great interest in agrivoltaics in the region: “A number of municipalities that want to build systems on their land have already approached us,” says Prof. Ulrich Schurr from IBG-2. The researchers provide active support here: “Whether it be municipalities, farmers, energy supply companies, investors, or citizens’ associations, everyone first needs to understand who plays what role.” For example, does a farmer want to equip their land with PV systems themselves and use the electricity directly? Or do they want to feed the electricity into the grid or make it available for the direct energy supply of a nearby residential area? Do farmers or landowners want to grant a company the right to build agrivoltaic systems on their land in return for a lease? “There are countless scenarios here,” says Schurr.

In providing support and advice, IBG-2 draws on its extensive experience in setting up its own agrivoltaics research plant near Morschenich-Alt. “Naturally, there is a great focus on ensuring a sensible interaction between plants and PV modules, but building regulations are also a major issue,” says Schurr. For example, there are clear restrictions on what can be built in outdoor areas. “Agriculture and PV systems bring together two aspects that have previously had little to do with each other in terms of regulation,” says Schurr. The Jülich team also realized this when it took months to obtain a permit for their research plant. “So far, there are no clear, uniform regulations for the regional, national, and European levels. This continues to deter many people,” says the plant researcher. “But we have learned a lot about the licensing processes, are passing on this knowledge, and expect that our Jülich precedent will simplify procedures in North Rhine-Westphalia in future.” Schurr also contributed to a paper for the German Federal Ministry for Economic Affairs and Energy: “The first statutory changes have already been introduced at federal level, but we have to keep track of developments.”

Christin Müller, the researching farmer

Christin Müller has been driving tractors across huge potato fields since she was twelve. “My parents have a farm in Titz, which I later hope to take over,” says the 24-year-old, who is studying agribusiness in Stuttgart. In 2022, she participated in the Agri-PV project as a master’s student in Dr. Onno Muller’s team at IBG-2 where she was able to combine both worlds: “On the one hand, I was able to research how Rhenish broad beans fare in the shade of PV systems throughout the year. On the other hand, I was able to provide a perspective and a lot of knowledge from practical agriculture.” And a good network: “I know a lot of farmers who give us great advice on the broad bean experiment and actively help us on site – for example, with pest control. I’m also able to exchange ideas with many farmers from my generation on an equal footing,” she says. Young farmers in particular are interested in innovative ways of using their fields because many farms are reaching the limits of their yields. Müller: “In view of rising energy prices, solar power generated on fields is likely to become increasingly valuable for farmers for their own consumption – for example, for power-hungry irrigation systems.” Agrivoltaics is particularly suitable for farms that regularly sell fruit and vegetables directly at weekly markets or farm shops: “The plants grow at different rates with the system – and don’t all ripen at the same time!” But back to the broad bean experiment: “The soil directly under the PV modules receives little rain, but a lot of light because the sun shines at an angle. Directly alongside the modules, however, the shade – and the rain – fall on the field,” explains Müller. What worked better? “In the spring, the beans initially grew faster in the sunny, dry area, but in the extremely hot summer, the plants in the damp shade clearly had the edge.”

Dr. Andreas Gerber, photovoltaics researcher

For agrivoltaic systems to be truly effective, plants and photovoltaic modules must be combined correctly. Dr. Andreas Gerber from IMD-3 (formerly IEK-5) is investigating how this works in practice together with colleagues from IBG-2 in Morschenich-Alt. The photovoltaics researcher and his team have developed the relevant PV measurement technology in collaboration with a company. “This involved us laying a lot of cables in muddy fields at heights of up to four metres at the end of 2021,” says Gerber. He now investigates the performance capabilities of the various types of PV modules in the field, some of which even move automatically with the sun. “We are also assessing whether technical problems occur more quickly due to wind and weather conditions at heights of up to four metres above the field,” says Gerber. “Incidentally, the entire system – including our measurement equipment and IBG-2’s robotics systems – is powered independently by our own green PV electricity!” At the same time, there is a software tool that can calculate how much light and shade reaches the plants at what time of day over the course of the year. “We are also conducting virtual tests to determine how large the spaces between the PV modules need to be,” says Gerber. “In addition, we can conduct preliminary testing on transparent PV modules, especially for cereals and other plants that need a lot of sun. These modules are currently being developed at HI ERN in Erlangen-Nuremberg thanks to Helmholtz funding. In future, all this will be combined with software that can predict the yields of individual plant species. “For me as a researcher, it’s a dream come true,” says Gerber. The software can be used in the region, but also worldwide, as it can be fed with different local weather data. Gerber: “In Africa, for example, the climate is completely different and there is much more sunlight than in the Rhineland.”

Angelina Steier, robotics expert

People regularly look on in awe at the agrivoltaics plant near Morschenich-Alt. Two metal measuring probes whizz back and forth above the field. They travel along a 1,200-metre-long steel rail mounted underneath the PV framework – like a small robot roller coaster. “Some of the PV installations have a height difference of two metres, and our probes use the rail system to overcome this,” explains robotics expert Angelina Steier from IBG-2. Currently still in the test phase, the two fully automatic battery-powered probes with different optical sensors will take over plant measurements for the agrivoltaics system this spring – and collect as much measurement data as possible automatically. “This allows us to simultaneously monitor the condition of the plants under the PV system and on the control area without PV modules at all times without damaging the plants,” explains the electrical engineer. When a probe’s battery is running low, it automatically returns to its charging station to “refuel” with stored solar power extremely fast. The two moving sensor platforms – metal cubes about one metre long – appear rather unspectacular at first glance. “But they are packed with innovative measuring instruments,” says Steier. She developed the two probes together with a specialist company, contributing her ten years of experience with other robotics systems from field experiments at IBG-2. “We use some lightweight measuring devices that we also use on our drones. At the same time, we are trying to integrate heavy sensors such as a 12-kilogram fluorometer, which can otherwise only be carried by our huge measuring robots.” However, the biggest difficulty is the weather: “The electronics are sensitive to heat, dust, and wetness. But it all has to work!” And the interested onlookers? They are always welcome, says Steier: “I think this great interest in innovations for the region is fantastic.”

Jochem Gerden, organic farmer in Düren

“We already have two large hall roofs covered with photovoltaic panels on our organic farm in Düren. We need a lot of energy just to store our vegetables in a cool place. So having our own solar power really cuts our costs. When I heard about the Agri-PV project at the start of 2021, I was interested right away. I quickly got in touch with the Jülich researchers and spent the past year helping to sow broad beans and nasturtium seeds in Morschenich-Alt. Like other farmers in the region, I advised IBG-2 as a practitioner, for example on how best to plough a field under such a system and which large machinery is needed for which crops. I immediately knew that growing sugar beet under agrivoltaic systems would not work because the huge sugar beet harvesters would not fit underneath. Since I was often on site and the Jülich researchers gave me excellent advice, I also learned a lot about agrivoltaics. We then considered whether we wanted to build such systems ourselves on some of our farmland, but also over the outdoor enclosure for our chickens, where they would protect the animals from hawks. Ultimately, however, the investment in agrivoltaic systems was too great for us. We don’t want to wait 20 years to see a return on investment. What makes construction so expensive at the moment is not the PV modules themselves, but the steel for the tall frames and the storage systems for the solar power. In the summer of 2022, Matthias Meier from IBG-2 asked us if we wanted to be part of a new research project. The plan is to install transparent PV modules on our greenhouses and polytunnels, i.e. on part of our 6,000 square metres of land planted with tomatoes, cucumbers, and strawberries. We are currently working on this together with Jülich. This is interesting for us as entrepreneurs because it allows us to learn a lot about this technology in practice on site. We can then make a good assessment about whether we want to install it ourselves on a larger scale in future. I don’t mind having researchers walking around our farm on a regular basis: I completed my own training at an experimental farm near Pulheim. So research is not new territory for me.”

The statements provided by the experts were compiled by Hanno Schiffer for Forschungszentrum Jülich’s staff magazine “inside” (updated in 2025) / Photos: Sascha Kreklau & Ralf-Uwe Limbach, Forschungszentrum Jülich.

Contact

- Institute of Bio- and Geosciences (IBG)

- Plant Sciences (IBG-2)

Room 413