Nanostructured Membranes | Dr. Marie Alix Pizzoccaro-Zilamy

About

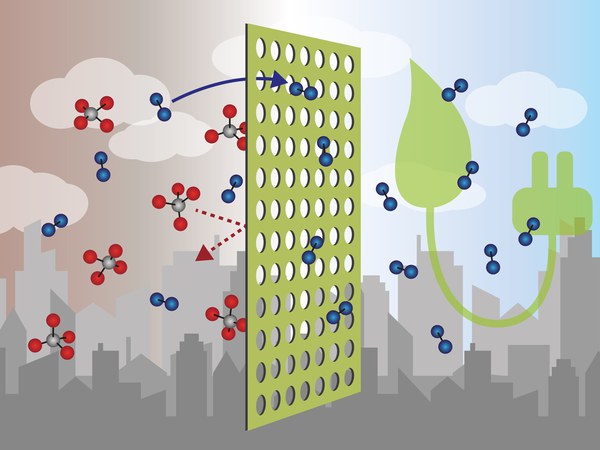

We develop novel types of two-dimensional zeolites and metal-organic frameworks (MOFs) membranes by combining novel synthesis approaches and surface polymerization methods to prepare defect-free and robust membranes with controlled morphology for gas separation applications. Another part of the research group is located at the University of Twente, Netherlands, and focuses on the engineering of organofunctionalized and/or reactive porous ceramic membranes with controlled surface properties for liquid filtration applications.

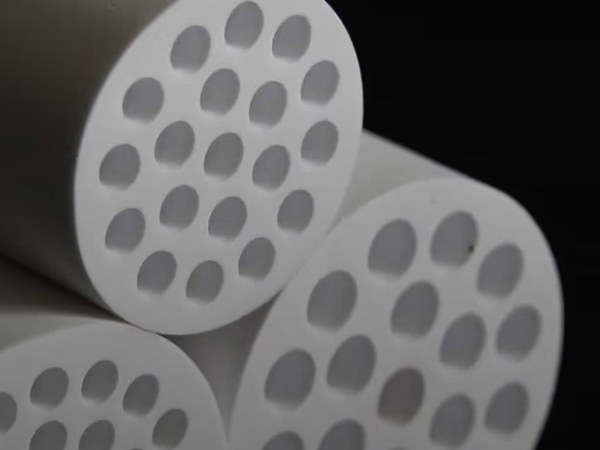

The core of our membranes is made of porous ceramic supports which brings the mechanical and chemical resistance to answer the needs of the challenging separations we are targeting.

Our shared vision is to use sustainable and green synthesis routes that can be easily scaled up.

Funded by the BMBF NanomatFutur competition with the project NanoMem.

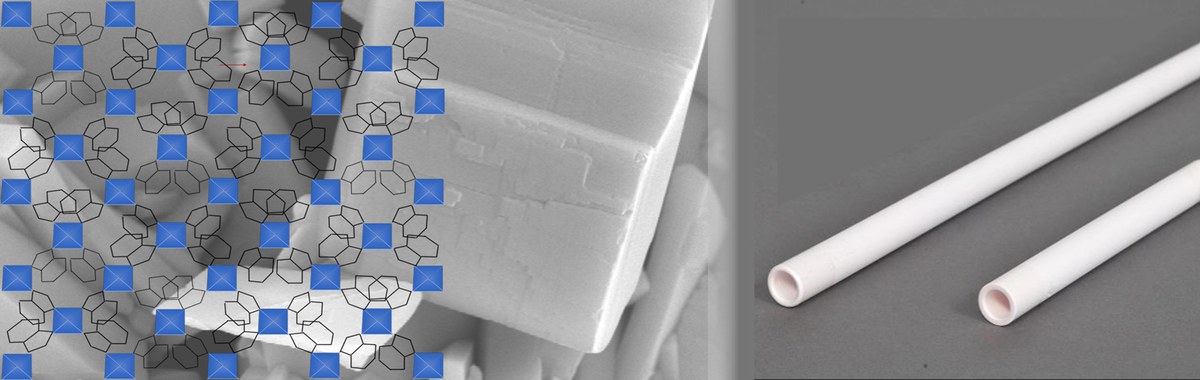

Hybrid 2D-based MOFs and zeolite membranes

Two-dimensional Metal-organic frameworks (MOFs) or zeolites are characterized by well-defined pores, that only let certain gases pass through their sub-nanometre-thick layers. We currently investigate the MOFs Zn2bim4 and the zeolite JDF-1 due to their promising H2 separation performance. Our work spans the synthesis of powders, processing in nanosheets, and characterization. Highly pure Zn2bim4 powders are prepared without pressurized vessels and harmless solvents. To grow MOFs and zeolite membranes, the secondary growth approach is used and requires a controlled seed morphology and purity. Nanosheet-based membranes are prepared via chemical exfoliation of the material and coating of the dispersion. To prepare robust membranes, we used organo-phosphonic-acid-based functionalized porous ceramic supports to favor the attachment of the membrane material. To heal the defects, controlled polymerization and click chemistry are employed to synthesize small units of polymer network starting from the membrane surface. Gas performance measurements under different pressure gradients are conducted. The stability of the membrane materials is also investigated in humid conditions. Due to the novelty of these materials, their long-term behavior under harsh conditions is also explored.

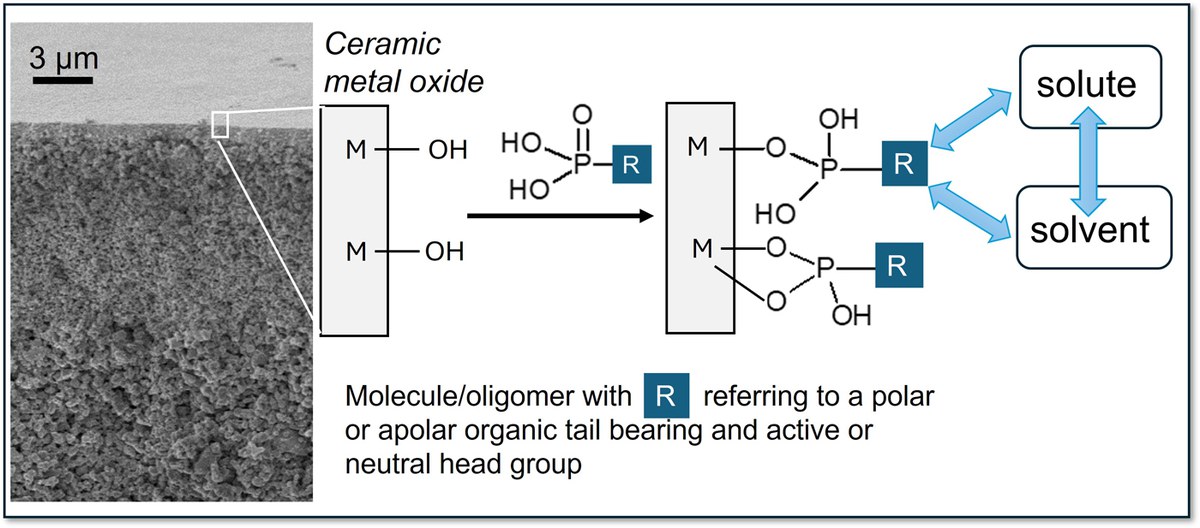

Organofunctionalized porous ceramic membranes

Surface modification of porous ceramic membranes by covalent attachment of molecules, short polymer chains, or polymeric networks provides the opportunity to prepare hybrid systems with controllable pore surface properties. This is particularly interesting for applications where the solvent-solute-membrane interactions drive the membrane separation performance. Examples are the case of organic solvent nanofiltration where favorable interactions between the organic solvent and the nanofiltration grafted ceramic membranes are desired to achieve high separation performance. Our current work focuses on the grafting of organo-based phosphonic-acid molecules or oligomers to form highly stable phosphorus-oxygen-metal bonds with the ceramic membrane surface. We develop simple surface grafting methods to prepare grafted ceramic membranes with pore diameters ranging from 2 to 400 nm. Our membranes can withstand challenging operation conditions in the area of desalination, organic solvent nanofiltration/solvent-resistant nanofiltration, and membrane crystallization applications.

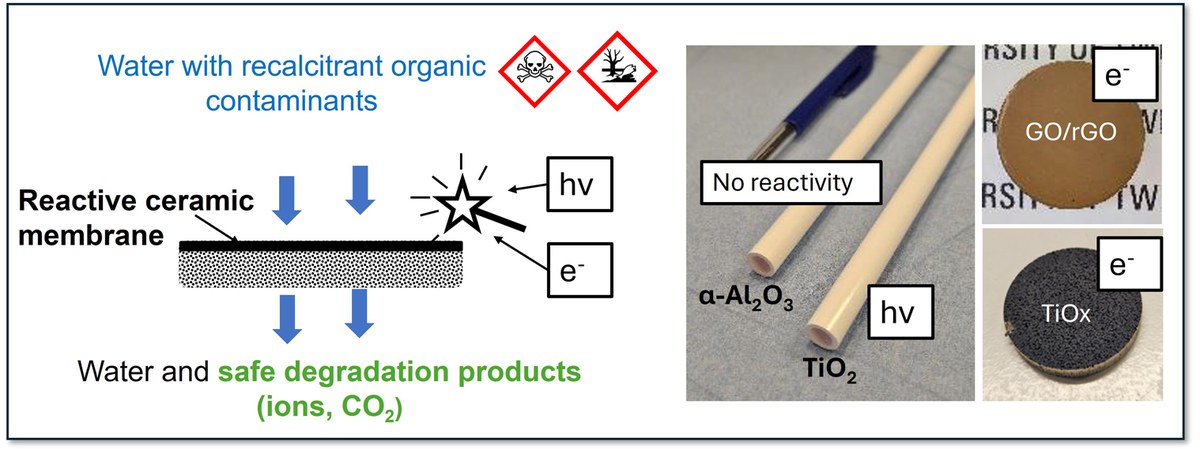

Reactive ceramic membranes

Ceramic membranes, owing to their strong chemical and thermal stability are receiving more and more attention in water treatment, water reuse, and reclamation. One of the main challenges is to avoid fouling during operation which will require backwashing and alkaline-chemical cleaning of the membrane. Reactive ceramic membranes that integrate advanced oxidation processes can be used to tackle this issue. This type of membrane relies on a combination of physical and chemical separations and has shown promising antifouling and chemical degradation abilities. In our team, we developed photocatalytic and electrochemical-reactive membranes made of Titanium-based metal oxides and graphene oxides derivate. We apply our expertise in ceramic membrane manufacturing to control the microstructure and study the influence on the membrane performance.